(I forgot to talk about span length...and a lot more, I have a lot to talk about this subject)

About span lenght:

On the ground floor, I have a unsupported span of 15 feet. I found an exemple of what my house could look like but with round wood instead.

Also, I want to do, if possible, the entire structure out of debarked round wood. I want to discover ways of using smaller diameter trees and use less wood, even at the cost of great effort. Another reason is that, to me, the natural shapes of trees are very pleasant to the eyes and appeal me beyond traditional timber framing). There are some exemples of interior of houses that integrate roundwood and strawbale wall construction. The wood I would use would be green, harvest from last winter OR the few last ones and stored hidden from the sun and well ventilate.

The floor support beams would be sawn on one side to make a level floor upstairs.

I like the idea of multiples small poles put next to each other to use has rafters (exemple in the video below).

I discovered Ben Law from UK. A green woodworker and a round wood timber framer with his famous cruck frame, or A frame design made from roundwood. In his book ''Round Wood Timber Framing'', he describes well the different joints he uses. Their is a video that shows the auto-construction of his house and this video was really a inspiring to me because it was the closest to how I see my construction, its also very instructive.

The cruck frame could be a solution for me (although I don't know where I could find such long and straight trees).

It's mainly pieces that goes from the corners of the bottom floor to the higher point of the roof. My only fear is that those timbers would make quite big obstacles to the sun trying to enter the house. In fact, the sun that heat the concrete slab of my house is an important source of heat in my design. The other is wood burning from a batch box rocket stove that would also heat water to go trough the concrete slab.

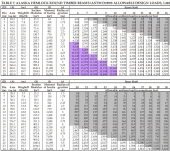

I agree with the idea of Roy Long to jut overkill the minimum strength requirement wit bigger diameter then what is asked or adding more bents to the frame.

Also, I can't just follow a chart and compare my wood with it. Checkings appearing overtime, important knots (because spruce as a lot of them as I know), tapering of wood trough the end. These are all affecting the strength of the timber. Ben Law have his general rule of thumb for his wood. He says that round timber is 50% stronger then the square milled wood you could get from it. I know that round wood has a few advantages over milled wood :

First, the round shape is stronger than the squared one.

Second, if you leave the shape of the tree as it was made, you keep the entire fiber structure and keep the tree has strong has it was standing in the forest, facing wind and bad waether. I also heard about japanese temple builders who places the round post in the same cardinal points alignement has it had standing in the woods. But that is just next level.

That said, I would not compare my wood withkiln dried, knotless, perfect wood. I would probably compare my round timbers to his equivalent once sawn.

I know that has Canadians and Americans, we have experiences with roundwood framing because of our log homes construction history. I did not find information about round wood structures and knowledge coming from log homes but I am sure there is some.

The Japanese have been using round wood also but I know only a littre about that. I am still very curious.

If you have any advise or knowleges to share, please do.