Kristaps Vinogulajs wrote:Hi,

were planing some hard reconstruction works in our old home. There are two rooms and one big hallway about 60 square meters (645 sft) all together.

And there are two old masonry heaters for heating all of that space, but they are very old and needs restoration, which costs a solid money.

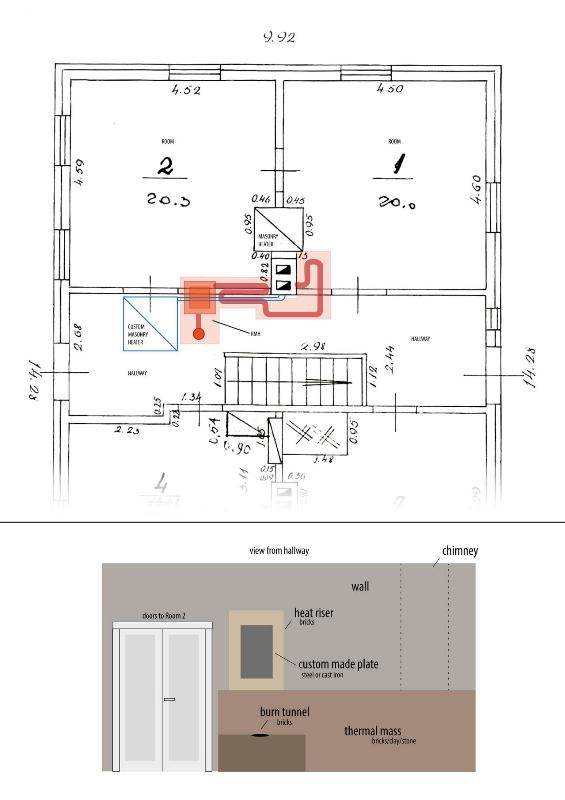

So i thought about RMH placed in between those rooms and hallway.

But the question is- how do i calculate the thermal mass size or the RMH size for the space needed to heat? Any suggestions?

BTW we are located in Eastern Europe, kind of a cold winters are here.

Masonry heaters size we have is about 1x1x2,5 m (3x3x8ft). And yes- they are pretty old and weak in heating.

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Kristaps Vinogulajs wrote:Thanks for replay Allen!

It took me a while to make this plan.

First of all i want to say i do not want a barrel and bench in this particular RMH design. Bearing that in mind i could go narrower and higher for the exhaust

-thermal mass part by stacking ductwork vertically.

Kristaps Vinogulajs :W.o.w., In a perfect world houses would be built around Rocket Mass Heaters RMHs, and we would not be talking about retro-fitting a

RMH into an existing structure ! THIS CAN BE DONE ! We can offer help our opinions and facts after that it will be your build, this will be a difficult build for

a 1st build,It will need to be tested out doors and then moved inside

There is an old saying about A Camel is a horse designed by a Committee' if you take the RMH design and try and place it inside a masonry heater shell you

are likely going to be unhappy with the result !

Lets look at my list of issues !Have you been to Rocketstoves.com to download Your copy of ''Rocket Mass Heaters", Right now this is the

oldest book in its brand new 3rd edition, and is 'The Book' used in almost all successful builds !

So i might building heat riser straightforward from bricks. And all outer shell as well from bricks. Inside the thermal mass made from clay,sand and stone.

As for immediate heat radiation i could use custom made plates(from steel or cast iron) placed in the heat riser walls.

The 1st job of our RMH is to get freaky hot- quickly, above 1800ºC, to do this we will actually limit the amount of mass that Our flame front is exposed to

until after the Top of the Heat Riser ! Mostly this is done by insulating Around the Combustion core, The feed tube, burn tunnel and the Heat Riser !

Also in the early part of the fire we want turbulence to increase contact between the Wood Fuel Gases and Oxygen at ignition temperatures- immediately

after the Top of the heat riser we want smooth flow of gasses and try and build our exhaust passages to promote that smooth flow, It sounds like you want

the outside wall of your Rocket to be square with sheet metal inserts on 3-4 sides to radiate of that heat, We have couple of problems here !

1) The top of the heat riser is the hottest part of the RMH, you will have the greatest amount of expansion and contraction with your metal plates and your

masonry having different expansion rates, making and keeping an air/ exhaust gases seal at that point will be extremely difficult ! The use of a barrel that

moves the sealing point down about 1 meter allows for prompt heat and cools the barrel are allowing for easier sealing !

2) Converting the Outside of the Heat Riser to a square to match the outer wall with sufficient gas passageway to ensure a smooth flow is difficult as we still

have the need to insulate the outside of the Heat riser at this point, This is an area where our designs are round and smooth and You sound like that is a

problem for you !

3) You should reconsider placing the feed tube in the hallway, this will mean that instead of just listening to your fire in the RMH, and automatically tending

it as needed, you will have to interrupt what you are doing, in order to get up and go check on your fire, Truly, your RMH can only serve you as well as you

serve it !

4) No benches- Again this is your build, my job is to point out ways to increase your options - I think that you have mentally looked at the Thermal Mass

Benches as A loss of space within your rooms. I am asking you to consider the Benches as fine pieces of built in furniture to be treasured and passed down

through your family, generation to generation Think of the pleasure of coming home and sitting on a pre- warmed bench in your hallway while changing to

indoor shoes, think of a small closet with your outside clothing hung up warm and dry. Instead of thinking of the benches as stealing floor area within Rooms

#1, and #2 think of them as additional storage space, at a convenient height for sitting you can have wall mounted shelving that folds back flat against your

walls or opens to provide more storage on two levels !

4b)stacking your horizontal ductwork is doable, and the vertically stacked elbows add back some of the horizontal footage lost to use of horizontal elbows,

this is a minor positive effect and you will need to come up with a layout with 1/2 that number of elbows !

A small correction: the other masonry heater i have in the hallway- it is built later, so its not in the house plan and i draw it with the blue stroke(see pic).

As i see by default the hallway was not provided by any heating. And it blocks door to room 2 so it will be removed anyway.

You have 2 entrances one at ether end of hallway, a door to room #1 a door from room#1 to room #2 and ablockeddoor from room #2 to hallway ?

The hallway and rooms floor is from wood(sand beneath it) and im going to replace it, so its easy to put in a concrete base for RMH.

The inner walls is from wood beams stacked vertically, except around masonry heater- there are bricks. Are these exposed beams, how thick, and are they

covered with plaster? I expect that the beams are not continuous and there is quite a lot of Plaster or Cob type infill, this can be re-cycled !

I believe that when you say Concrete and I say Concrete we are using different final products and don't want to comment here except about adding insulation

under the slab our around your perimeter walls ! Extra mass must be provided under the RMHs Burner Base to protect your Concrete from Thermal damage.

Im planing to place RHM in between the rooms and the hallway underneath the wall that separates rooms from hallway. (see pic , planned RMH is marked red)

And i do not need that space in the hallway between stairway and the wall. Main house entrance is at the left side of the hallway, the secondary entrance is on

the right. No dimensions for RMH at this point. And im not sure about heat efficiency in the room nr 1 by this design/placement of the RMH.

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Glenn Herbert wrote:That sounds excellent. If you make a bell around the chimney, with a RMH core next to it inside the bell, you would want to have the heat riser on the opposite side of the chimney from the cleanout door, so the gases must flow around both sides of the chimney and give up heat evenly. If the cleanout is in room 1, you would want the riser on the room 2 side of the chimney as in my crude sketch, just keeping the cleanout door open for the bell exit to the chimney.

You say a masonry heater will have metal doors; I presume they have an adequate sealing system so they don't leak when they heat up or cool down.

1

1

|

They worship nothing. They say it's because nothing is worth fighting for. Like this tiny ad:

New Year, New Earth Summit - register for free!

https://permies.com/t/367268/Year-Earth-Summit-register-free

|