Luke Mitchell wrote:Those fibers are sometimes called "straps" and are the origin of the expression "strapping lad" (meaning "strong young man", for those unfamiliar with the expression). Cutting the straps with an axe was considered to be the hardest of the tasks when splitting logs.

Cargo bikes are cool

4

4

Nancy Reading wrote:Thanks for sharing this Edward - very impressed also by that saw.

It's nice to know the tree was obviously felled for a good reason. I was going to ask if you had a use for a big pipe or trough when I saw that hollow trunk, but I guess you're past that stage now.

Cargo bikes are cool

2

2

C. Letellier wrote:Another type of system to look at. Froe and Maul.

Cargo bikes are cool

10

10

Cargo bikes are cool

2

2

“It’s said war—war never changes. Men do, through the roads they walk. And this road—has reached its end.”

7

7

6

6

8

8

Cargo bikes are cool

7

7

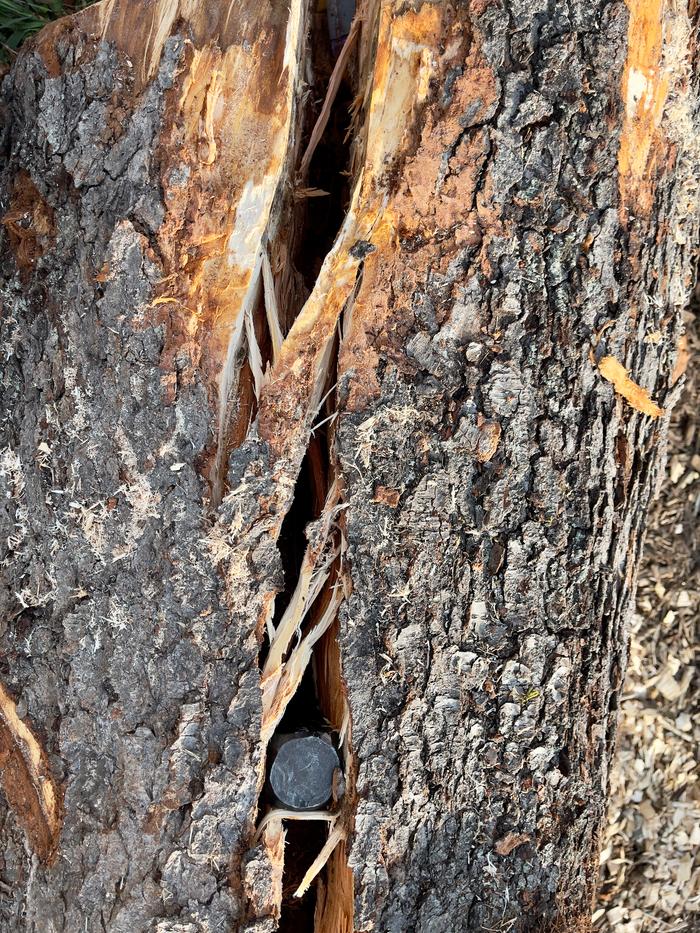

For good reason! My neighbor with a mill bought a quality metal detector after running into a decorative bracket someone had hung off a tree and forgotten to remove - the tree had grown completely over it and he broke several teeth on his big blade. Luckily it was the sort of blade that he could replace teeth on, but it still cost him a half a day removing, fixing and remounting the blade!Randy Butler wrote:Commercial loggers and mills are very wary of logs with unknown origins, but the little guys are sometimes set up with specialty blades for just that purpose.

Visit Redhawk's soil series: https://permies.com/wiki/redhawk-soil

How permies.com works: https://permies.com/wiki/34193/permies-works-links-threads

3

3

Fish heads fish heads roly poly fish heads

3

3

Argue for your limitations and they are yours forever.

8

8

Small-holding, coppice and grassland management on a 16-acre site.

11

11

“It’s said war—war never changes. Men do, through the roads they walk. And this road—has reached its end.”

7

7

Jordan Holland wrote:If you look at the pictures of riving so far, you may notice something they all have in common: They are splitting down the middle. From my experiences with logs and shakes, this is basically essential. If you try to split a thinner piece from a thicker piece, what almost always happens is the thinner piece gets thinner and thinner until it tapers to nothing.

Jordan Holland wrote:

To anyone who has not used a froe, I can say the thought of trying to split a log with one does not tempt me much.

Jordan Holland wrote:

And think, if people were willing to take a saw and cut the entire length of a log multiple times to make boards in yesteryears, it is likely because it was faster/easier/better than riving them. Food for thought.

Small-holding, coppice and grassland management on a 16-acre site.

Become extra-civilized!

4

4

Coydon Wallham wrote:Would a riven board be significantly stronger than a sawn dimensional equivalent given that it is not being cut through its grains?

5

5

L. Johnson wrote:

Coydon Wallham wrote:Would a riven board be significantly stronger than a sawn dimensional equivalent given that it is not being cut through its grains?

The theory is yes, but more stable than strong. The main advantage of riving is getting extremely dimensionally stable wood. You end up wasting a lot of material in riving. That's why round wood is even better for structural work. Just harder to work with.

“It’s said war—war never changes. Men do, through the roads they walk. And this road—has reached its end.”

1

1

Jordan Holland wrote:Of note is also the tendency for rough split surfaces to rot less quickly because cutting through the fibers to make the sides perfectly flat gives many opportinities for water to be absorbed deep into the wood due to capillary action, since it is the ends of fibers that most readily absorb water.

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

4

4

randyeggert.com

5

5

Mike Haasl wrote:

Jordan Holland wrote:Of note is also the tendency for rough split surfaces to rot less quickly because cutting through the fibers to make the sides perfectly flat gives many opportinities for water to be absorbed deep into the wood due to capillary action, since it is the ends of fibers that most readily absorb water.

I've heard this too but don't the torn/ripped rough fibers still have just as many exposed holes that can capillarilly absorb water?

“It’s said war—war never changes. Men do, through the roads they walk. And this road—has reached its end.”

9

9

Randy Eggert wrote:

It strikes me that some of them are working too hard, not letting the saw do the work.

“It’s said war—war never changes. Men do, through the roads they walk. And this road—has reached its end.”

3

3

Pearl Sutton wrote:Edward!

Money making opportunity! Find out what sizes people on permies need, and sell cuts :D

Cherry wood is SO beautiful! Imagine wood spoons out of cherry....

I know there is a wood turner local to me who would probably buy wood like that if it were here, bet there are some near you.

Your friend isn't always right and your enemy isn't always wrong.

4

4

Randy Eggert wrote:Returning to the original question about cutting big logs without a chainsaw. Back in 1989 I was a cook on horsepack trips into the Wyoming wilderness. The two outfitters were contracted with the Forest Service to clear the trails we used, and since it was designated wilderness no power tools were allowed. They had a two-person crosscut saw strapped to one of the mules. Every time we came across a log, they dismounted, took off the saw, and cut the log in no time. Counting the time to start a chainsaw, fuel it, oil it, etc., I swear the two-person saw was faster. It takes practice, though. I did some cuts with one of them, and I was lousy at it, couldn't get the timing right.

Anyway, if you're set on not using a chainsaw, get a good two-person saw, find a partner, and practice. You'll cut through the logs quickly.

I checked out a few Youtube videos of people using two-person saws. It strikes me that some of them are working too hard, not letting the saw do the work. I like the rhythm that these two have:

Become extra-civilized!

4

4

Become extra-civilized!

7

7

Nancy Reading wrote:Thanks for sharing this Edward - very impressed also by that saw.

It's nice to know the tree was obviously felled for a good reason. I was going to ask if you had a use for a big pipe or trough when I saw that hollow trunk, but I guess you're past that stage now.

Cargo bikes are cool

5

5

Phil Swindler wrote:

I have a desk and matching dresser made of cherry that I made several years ago.

I personally cringe at the thought of those nice logs going up in smoke.

I'd wonder about finding someone with a portable lumber mill. Or maybe get them hauled to a mill.

Cargo bikes are cool

5

5

|

Obey! Obey this tiny ad!

Learn Permaculture through a little hard work

https://wheaton-labs.com/bootcamp

|