posted 6 years ago

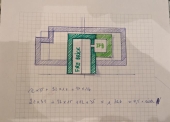

Benen, the gap is the distance between heat riser and the flue's edge.

So if i get it correctly, 7 inches.

Tho, you have a restriction, in the 2 inches at the bottom. That means that only the two sides and the top of the flue's edge have plenty of space. Nothing much to worry about mind you. In fluid mechanics it is often said that the boundary layer, between stalling against the pipe's wall, and full speed is about 3cm. So gases in your 5 incher have only a tube at the middle, of 56mm, to go at fulle speed. Well, this is all verry theoretical. Since hot gases behave differently depending on their temperature.

I would try running it with two or three times the recommended air intake size, at first. And if it still pulses (oh yeah! :D ) i would enlarge that flue entrance.