4

4

1

1

Nathan Strumfeld wrote:The things I'm a little unsure about are: the hole in the bottom/top of the clay pot, would 4" or so work? The cob mix: I'm planning on making a form and building it up from the bottom, any special considerations for the mix to ensure stability?

Silence is Golden

For all your RMH needs:

dragontechrmh.com

3

3

1

1

Silence is Golden

For all your RMH needs:

dragontechrmh.com

3

3

Ask me about food.

How Permies.com Works (lots of useful links)

2

2

3

3

Silence is Golden

For all your RMH needs:

dragontechrmh.com

2

2

Julia Winter wrote:Your drawing has the heat getting directed sideways into a barrel and then going down? It's odd for heat to go down. I don't know if that's going to work. I mean, I know that it goes down in a rocket mass heater, but it doesn't need to spread out evenly, it just needs to leave the barrel and heat the mass. I don't see how the intense heat coming out of the heat riser is going to heat anything but the very top (and not just the top, but one side of the top) of the inner clay oven, and I can imagine flames making their way up around the clay oven at the top.

2

2

1

1

William Bronson wrote:I love your idea for this!

I don't think you are asking too much of the rocket, after all there isn't a bench to push exhaust through, just the barrel.

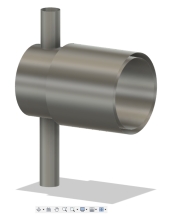

Your idea isn't far off the basic J rocket exhausting into a barrel.

I'm curious though, is deep and narrow ideal for a tandoor oven?

The bottom reaches seem like they would be hard to use without burning the crap out of yourself!

A little googling make me think the deeper part of the tandoor is there to hold the coals, which should be unnecessary in this design.

2

2

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

thomas rubino wrote:Hi Nathan;

Yes , I have made bunches of cob using dry fireclay. No rocks, it is a joy to work with.

3 part sand to 1 part clay. Here #50 sacks of fireclay cost from $9-$20

I usually buy bagged builders sand as well.

It will crack if you do not have enough sand but it is much more heat resistant.

2

2

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

6

6

Works at a residential alternative high school in the Himalayas SECMOL.org . "Back home" is Cape Cod, E Coast USA.

Rebecca Norman wrote:Hi from Tandoor-land, Nathan!

We bought a tandoor liner a couple of years ago for our school. I'd say it was almost 2 feet in diameter at the widest part, and 1.5 feet maybe, at the top. It was a fired clay pot, bottomless, so we built it into an adobe and cob structure, with the outer gaps filled with sand.

Unfortunately, right when we finally installed it, our previous cook, a young guy who had worked at his uncle's tandoor bakery, left and a new cook who had never used a tandoor started. The new cook (who had hairy arms -- which might make a difference!) basically wouldn't use it because he said he was getting burnt (even though I think it was only coals in the bottom, not flames, when you slap the dough in). So in your design, one issue I see is that if everything else works (and I have some of the same concerns as people up above on this page), you'd have to slap the dough in while the fire is raging up through the baking chamber. Is there a way to have a bypass that you could open while putting dough in, and then close again for baking? Or are you thinking you'd preheat the whole thing and then let the fire die and bake?

For tandoor-roasting things on skewers, a local friend of mine has started a business with an Australian partner making Himalayan Rocket Stoves. These are to be used like woodstoves for heating in winter, and are not mass heaters, as the houses here tend to be adobe so the house itself can serve as the thermal mass. They kept two removable round iron plates on the top for cooking: one over the horizontal burn tunnel, and one directly over the heat riser. My local friend takes the top off the heat riser and sticks skewers of yummies down. They roast in a minute or two, and then we pull them out, close the top again, and devour the yummies. He roasts marinated paneer, green pepper capsicum, mushrooms, onions, red meat, or chicken, and other veggies, in it. Here's a video of roasting paneer in the rocket tandoor.

2

2

Nathan Strumfeld wrote:I have a barrel that had motor oil in it, I can still smell some of the residue. Any recommendations for cleaning/prepping it before grinding the bottom off without blowing myself up? I'm thinking I'll have the side without the bungs facing up. I'm not sure if just swishing some soapy water, then dumping it out is enough? Filling the whole thing up with water seems like a pain, especially since I'd need to then flip it upside-down.

Also, my base I'm going to set this all on has about a couple inches of cob with plenty of straw mixed in. Should I do another inch of perlite/clay slip for insulation on the bottom? Or is the cob enough?

Silence is Golden

For all your RMH needs:

dragontechrmh.com

2

2

1

1

2

2

1

1

Silence is Golden

For all your RMH needs:

dragontechrmh.com

2

2

2

2

2

2

1

1

1

1

1

1

Silence is Golden

For all your RMH needs:

dragontechrmh.com

1

1

1

1

Silence is Golden

For all your RMH needs:

dragontechrmh.com

1

1

2

2

1

1

Silence is Golden

For all your RMH needs:

dragontechrmh.com

1

1

| I agree. Here's the link: http://stoves2.com |