1

1

1

1

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

1

1

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

1

1

1

1

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

1

1

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

1

1

1

1

1

1

Silence is Golden

For all your RMH needs:

dragontechrmh.com

1

1

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

1

1

1

1

Silence is Golden

For all your RMH needs:

dragontechrmh.com

2

2

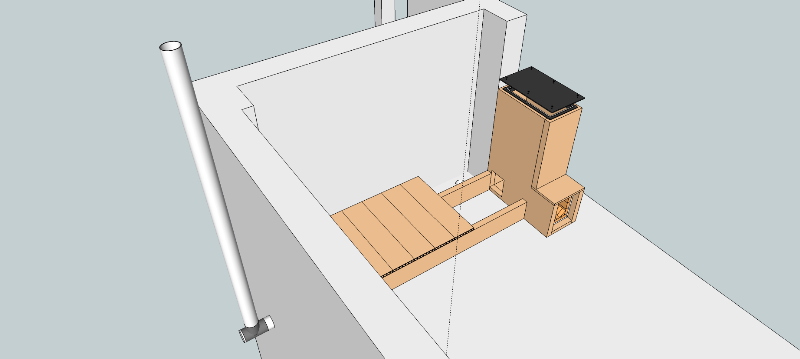

Robbie Mendelssohn wrote:Can I make the pipe in the mass thicker to get the required ISA?? making it kind of like a bell?

Silence is Golden

For all your RMH needs:

dragontechrmh.com

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Robbie Mendelssohn wrote:I say it would be a bit like a bell in that it has extra volume, being of larger diameter and the exhaust would still be moving slowly compared to when it narrows at the vertical chimney. I bought the tubes today so I hope I'm right...

I did read the post to the end as recommended and was thoroughly entertained, I like the science fair interlude.

Is that ytong block wrapping the firebox? I was considering using it until I dug deep and spend a staggering quantity on ceramic fibreboard.

Here's a question.... To make a slab for the top instead of steel, can I cast one like someone said here with clay and sand and arlite? I can't find a refractory slab around here.... And, why arlite? Isn't it insulating, rather than accumulating,,? Also, I'd hate to see it collapse and crush my fibreboard riser :-p

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

2

2

1

1

Robbie Mendelssohn wrote:Thanks again to all who have helped out, I'm now constructing the bell...I have a technical question: I have scaled the core to a 175mm system as that is the available tube. But now my floor channel is 67mm wide. I can only get 70x30 or 60x30 tube, so should I go bigger, or smaller? or do I need to fabricate my own tube, which will be tricky....? Thanks guys!!!

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

1

1

2

2

|

Power corrupts. Absolute power xxxxxxxxxxxxxxxx is kinda neat.

Home Mushroom Cultivation Class Recordings from Fungi Ally

https://permies.com/t/212599/Home-Mushroom-Cultivation-Class-Recordings

|