8

8

3

3

Check out Redhawk's soil series: https://permies.com/wiki/redhawk-soil

3

3

3

3

Country oriented nerd with primary interests in alternate energy in particular solar. Dabble in gardening, trees, cob, soil building and a host of others.

2

2

A human being should be able to change a diaper, plan an invasion, butcher a hog, conn a ship, design a building, write a sonnet, balance accounts, build a wall, set a bone, comfort the dying, take orders, give orders, cooperate, act alone, solve equations, analyze a new problem, pitch manure, program a computer, cook a tasty meal, fight efficiently, die gallantly. Specialization is for insects.

-Robert A. Heinlein

2

2

Works at a residential alternative high school in the Himalayas SECMOL.org . "Back home" is Cape Cod, E Coast USA.

Rebecca Norman wrote:It would help if you mention C or F after you mention "degrees." If your reflector is very well focused, it could sometimes burn through or melt spots of the metal, so you might need to use high temperature steel or something.

A human being should be able to change a diaper, plan an invasion, butcher a hog, conn a ship, design a building, write a sonnet, balance accounts, build a wall, set a bone, comfort the dying, take orders, give orders, cooperate, act alone, solve equations, analyze a new problem, pitch manure, program a computer, cook a tasty meal, fight efficiently, die gallantly. Specialization is for insects.

-Robert A. Heinlein

4

4

1

1

A human being should be able to change a diaper, plan an invasion, butcher a hog, conn a ship, design a building, write a sonnet, balance accounts, build a wall, set a bone, comfort the dying, take orders, give orders, cooperate, act alone, solve equations, analyze a new problem, pitch manure, program a computer, cook a tasty meal, fight efficiently, die gallantly. Specialization is for insects.

-Robert A. Heinlein

3

3

2

2

2

2

Check out Redhawk's soil series: https://permies.com/wiki/redhawk-soil

6

6

2

2

Community Building 2.0: ask me about drL, the rotational-mob-grazing format for human interactions.

2

2

A build too cool to miss:Mike's GreenhouseA great example:Joseph's Garden

All the soil info you'll ever need:

Redhawk's excellent soil-building series

3

3

A human being should be able to change a diaper, plan an invasion, butcher a hog, conn a ship, design a building, write a sonnet, balance accounts, build a wall, set a bone, comfort the dying, take orders, give orders, cooperate, act alone, solve equations, analyze a new problem, pitch manure, program a computer, cook a tasty meal, fight efficiently, die gallantly. Specialization is for insects.

-Robert A. Heinlein

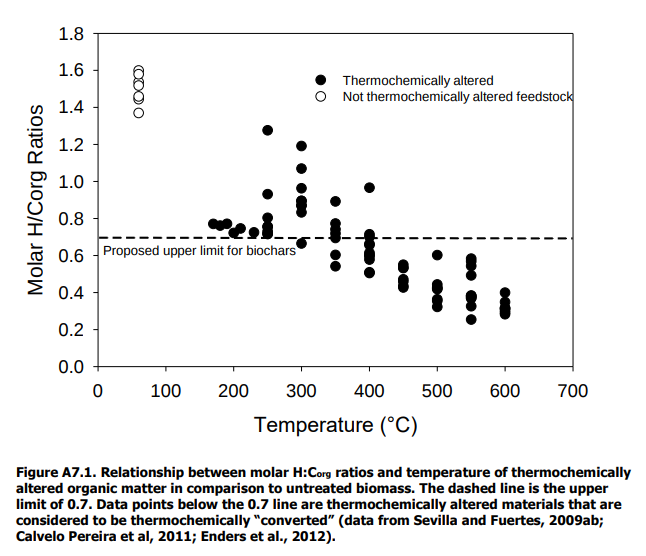

Phil Stevens wrote:Jim, biomass pyrolysis is exothermic and in the case of woody matter there is more than sufficient energy in the feedstock to drive the entire process (as long as the wood is dry). So if you're capturing the syngas output of a batch in your solar retort, it will be more than enough to "cook" another batch of equal mass. This is why pit and kontiki methods are so effective: we use that process heat right at the source and dispense with lots of technology to capture, scrub, store, and transport the syngas. Flame cap burns easily achieve 600-700C in the active zone.

So, as John suggests, you could use the solar concentrator to kiln-dry the feedstock on its way into your retort, where the output gas would provide all the heat required beyond startup.

[edit] I just noticed you were aiming for process temps of 600-700F. This won't produce biochar, as it's nowhere near hot enough to drive off the volatile HC compounds and form the aromatic C bonds. What you will get out of that will be torrefied wood. We usually consider 450C to be a minimum for high-quality biochar that does all the good stuff in soil.

Community Building 2.0: ask me about drL, the rotational-mob-grazing format for human interactions.

2

2

1

1

Community Building 2.0: ask me about drL, the rotational-mob-grazing format for human interactions.

2

2

Phil Stevens wrote:Jim, biomass pyrolysis is exothermic and in the case of woody matter there is more than sufficient energy in the feedstock to drive the entire process (as long as the wood is dry). So if you're capturing the syngas output of a batch in your solar retort, it will be more than enough to "cook" another batch of equal mass. This is why pit and kontiki methods are so effective: we use that process heat right at the source and dispense with lots of technology to capture, scrub, store, and transport the syngas. Flame cap burns easily achieve 600-700C in the active zone.

So, as John suggests, you could use the solar concentrator to kiln-dry the feedstock on its way into your retort, where the output gas would provide all the heat required beyond startup.

[edit] I just noticed you were aiming for process temps of 600-700F. This won't produce biochar, as it's nowhere near hot enough to drive off the volatile HC compounds and form the aromatic C bonds. What you will get out of that will be torrefied wood. We usually consider 450C to be a minimum for high-quality biochar that does all the good stuff in soil.

Nails are sold by the pound, that makes sense.

Soluna Garden Farm -- Flower CSA -- plants, and cut flowers at our farm.

3

3

Moderator, Treatment Free Beekeepers group on Facebook.

https://www.facebook.com/groups/treatmentfreebeekeepers/

1

1

A human being should be able to change a diaper, plan an invasion, butcher a hog, conn a ship, design a building, write a sonnet, balance accounts, build a wall, set a bone, comfort the dying, take orders, give orders, cooperate, act alone, solve equations, analyze a new problem, pitch manure, program a computer, cook a tasty meal, fight efficiently, die gallantly. Specialization is for insects.

-Robert A. Heinlein

1

1

1

1

2

2

1

1

Carbon Negative Stove plans available at:

https://www.carbonconsciouscreations.com

4

4

2

2

I want to be 15 again …so I can ruin my life differently.

1

1

Check out Redhawk's soil series: https://permies.com/wiki/redhawk-soil

D Fritschen wrote:... Because if you use solar power. Or any power then you get to collect all the syngas and synoil. Think of it like a battery:). I use solar power to make fuels during the day. When I need diesel or cooking or heating gas I have it ready with the maximum volume possible.

Visit Redhawk's soil series: https://permies.com/wiki/redhawk-soil

How permies.com works: https://permies.com/wiki/34193/permies-works-links-threads

|

I knew I would regret that burrito. But this tiny ad has never caused regrets:

permaculture thorns, A Book About Trying to Build Permaculture Community - draft eBook

https://permies.com/wiki/123760/permaculture-thorns-Book-Build-Permaculture

|