1

1

Every family should be an island of self sufficiency and free of grid bondage so that we can all have more time and ability to make the world a better place versus sprinting in the rat race!

6

6

Iterations are fine, we don't have to be perfect

My 2nd Location:Florida HardinessZone:10 AHS:10 GDD:8500 Rainfall:2in/mth winter, 8in/mth summer, Soil:Sand pH8 Flat

1

1

S Bengi wrote:

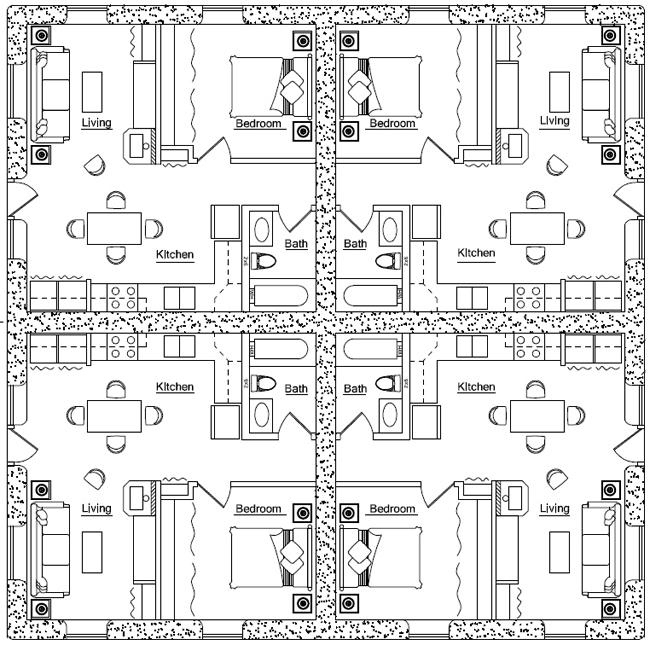

So you could fit 4 such houses under the barn with about 12ft between every house

How Permies works: https://permies.com/wiki/34193/permies-works-links-threads

My projects on Skye: The tree field, Growing and landracing, perennial polycultures, "Don't dream it - be it! "

5

5

3

3

Every family should be an island of self sufficiency and free of grid bondage so that we can all have more time and ability to make the world a better place versus sprinting in the rat race!

2

2

Iterations are fine, we don't have to be perfect

My 2nd Location:Florida HardinessZone:10 AHS:10 GDD:8500 Rainfall:2in/mth winter, 8in/mth summer, Soil:Sand pH8 Flat

Every family should be an island of self sufficiency and free of grid bondage so that we can all have more time and ability to make the world a better place versus sprinting in the rat race!

1

1

Every family should be an island of self sufficiency and free of grid bondage so that we can all have more time and ability to make the world a better place versus sprinting in the rat race!

3

3

Iterations are fine, we don't have to be perfect

My 2nd Location:Florida HardinessZone:10 AHS:10 GDD:8500 Rainfall:2in/mth winter, 8in/mth summer, Soil:Sand pH8 Flat

1

1

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

1

1

Every family should be an island of self sufficiency and free of grid bondage so that we can all have more time and ability to make the world a better place versus sprinting in the rat race!

Every family should be an island of self sufficiency and free of grid bondage so that we can all have more time and ability to make the world a better place versus sprinting in the rat race!

Greg Payton wrote:Mike Haasl we could dig it out a bit to level it especially. So you're thinking of just doing dirt + something like 6 mil poly plastic sheeting + an enormous amount of sawdust with borax (powered or wetted with a solution?) and then a floor? I fear lumber prices might be more than cement right now, no?

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

2

2

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

Every family should be an island of self sufficiency and free of grid bondage so that we can all have more time and ability to make the world a better place versus sprinting in the rat race!

2

2

2

2

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

2

2

Iterations are fine, we don't have to be perfect

My 2nd Location:Florida HardinessZone:10 AHS:10 GDD:8500 Rainfall:2in/mth winter, 8in/mth summer, Soil:Sand pH8 Flat

1

1

Every family should be an island of self sufficiency and free of grid bondage so that we can all have more time and ability to make the world a better place versus sprinting in the rat race!

1

1

Every family should be an island of self sufficiency and free of grid bondage so that we can all have more time and ability to make the world a better place versus sprinting in the rat race!

1

1

Iterations are fine, we don't have to be perfect

My 2nd Location:Florida HardinessZone:10 AHS:10 GDD:8500 Rainfall:2in/mth winter, 8in/mth summer, Soil:Sand pH8 Flat

1

1

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

1

1

Every family should be an island of self sufficiency and free of grid bondage so that we can all have more time and ability to make the world a better place versus sprinting in the rat race!

1

1

Every family should be an island of self sufficiency and free of grid bondage so that we can all have more time and ability to make the world a better place versus sprinting in the rat race!

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

Every family should be an island of self sufficiency and free of grid bondage so that we can all have more time and ability to make the world a better place versus sprinting in the rat race!

Iterations are fine, we don't have to be perfect

My 2nd Location:Florida HardinessZone:10 AHS:10 GDD:8500 Rainfall:2in/mth winter, 8in/mth summer, Soil:Sand pH8 Flat

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

Every family should be an island of self sufficiency and free of grid bondage so that we can all have more time and ability to make the world a better place versus sprinting in the rat race!

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

| I agree. Here's the link: http://stoves2.com |