5

5

4

4

4

4

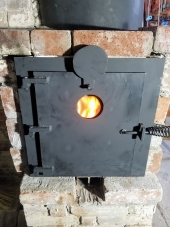

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

4

4

Randy Butler wrote:

One thing you may want to consider is your heating needs - do you want heat right away (metal barrel), or do you want something with longer run time, but delayed start (masonry bell).

4

4

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

2

2

thomas rubino wrote:Hi Lauren;

What part of the world are you building in?

How cold will it get and for how long will it remain coldish?

All RMHs of every design with or without a barrel will need time to heat their mass.

Radiant heat can be supplied with a barrel or other metal surfaces near the riser.

If you are thinking of a bench, were you planning on a piped bench? Or a bell bench?

Tell us more about your plans, and what your home is built out of.

2

2

thomas rubino wrote:

The first thing I want to talk about is your comment about venting thru the wall.

I hope you plan to go thru the wall horizontally and then put vertical sections on.

If you are hoping to stay horizontal, you will most likely have draft and wind issues.

3

3

. When I fire it up it is always stone cold (sometimes even freezing). Nevertheless, the barrel heats up in less then 5mins and the bench is handwarm at the near side 40mins later. After 1hour the whole thing is warm to the touch and the fire is all embers covered with white ash. Without more wood it will cool down to lukewarm in about 2hours (a little faster, if it's really cold outside).

. When I fire it up it is always stone cold (sometimes even freezing). Nevertheless, the barrel heats up in less then 5mins and the bench is handwarm at the near side 40mins later. After 1hour the whole thing is warm to the touch and the fire is all embers covered with white ash. Without more wood it will cool down to lukewarm in about 2hours (a little faster, if it's really cold outside).

4

4

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

1

1

thomas rubino wrote:

Well, let's see. To start an 8" batch box is way more than you need, an extended length 6" would do fine.

Have you considered building an 8" J tube rocket rather than a batch box?

They require feeding every 45 minutes or so but are very simple to build.

Batch boxes are also simple to build. They do require some metal parts, but perhaps your husband can build them.

thomas rubino wrote:

I suspect a bell system would only work if you first exit your metal box with a vertical pipe and then pass horizontally thru the wall.

After you get outside, you can try different ideas for leaving it flat or adding another vertical.

Glenn Herbert wrote:Thin metal bell walls there would not store a noticeable amount of heat if insulated outside so would not be counted.

4

4

3

3

Lauren Knickman wrote:

I discovered the J tube rocket first, but now I only have eyes for the strat chamber batch box. Easier build, less tending, lower maintenance, visible flames... what more could a girl want?? I think I've settled on a 150mm (7 inches?) heat riser in a sidewinder configuration.

I guess I could put a 30-50cm vertical portion on the flue once it exits my house, but there's the definite limit of my upstairs neighbor's balcony. Hopefully it will work magically and my neighbors won't even notice it, but if they do... as my dad always said, "It's easier to get forgiveness than permission". I figure worst could happen, I'll have to take it down, but that's a gamble I'm willing to take.

regards, Peter

|

Every snowflake is perfect and unique. And every snowflake contains a very tiny ad.

permaculture bootcamp - gardening gardeners; grow the food you eat and build your own home

https://permies.com/wiki/bootcamp

|