1

1

I want to be 15 again …so I can ruin my life differently.

1

1

Tradition is not the worship of ashes, but the preservation of fire.

2

2

Elyes Kallel wrote:HI,

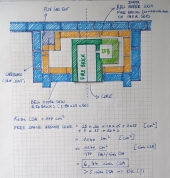

I have a steel bell with such dimensions (view attachment 1). Height is, obviously, too long compared to diameter.

I have been inspired by the "Liberator rocket heater" model (attachment 2). Unfortunately I don't have the dimensions of this model

Concerning the burning chamber, I am planning to insulate it from inside with a 2 cm refractory cement layer cast

So my questions are:

- What is the best height for a 40 cm bell ?

- What about the dimensions of the J tube ?

- Is castable refractory cement a good insulation material? and is 2 cm thinkness OK ?

Silence is Golden

For all your RMH needs:

dragontechrmh.com

2

2

Gerry Parent wrote:

Elyes Kallel wrote:HI,

I have a steel bell with such dimensions (view attachment 1). Height is, obviously, too long compared to diameter.

I have been inspired by the "Liberator rocket heater" model (attachment 2). Unfortunately I don't have the dimensions of this model

Concerning the burning chamber, I am planning to insulate it from inside with a 2 cm refractory cement layer cast

So my questions are:

- What is the best height for a 40 cm bell ?

- What about the dimensions of the J tube ?

- Is castable refractory cement a good insulation material? and is 2 cm thinkness OK ?

Hi Elyes.... Welcome to the Permies RMH forum.

What size of building are you trying to heat? Dimensions will vary according to whether you choose a typical 6" or 8" J tube.

Do you have experience with casting? I know several seasoned builders here have and it seems a lot harder way to start a first build.

Have you instead considered fire brick?

What is the shape of your steel bell? Round or square?

3

3

3

3

Finally! An Online Garden Master Course for permies!

How Permies.com Works

Garden Master Program video course and ebook guide

| I agree. Here's the link: http://stoves2.com |