Peter Peterson : Welcome to Permies.com* and a Big welcome to the wood burning and Rocket

stove Mass Heaters Forum Threads ! i expect that you will gain a

lot of members eager to follow your New Thread as possible add-ons to their Wood Stoves, but you will have a harder sell amongst the 'Rocket Mass Heater R.M.H. Crowd. You

will certainly greatly disturb the ' but we've always done it this way group " Good on You, We need new members that break us out of our preconceived Ideas.

I may not understand what you are suggesting, we need a complete exhaust system with a discharge Chimney, for the same reason we need an 'other end ' to our Alimentary

system, to keep from being constipated

I will let others tackle the many reasons pro and con for Not deviating from our present way of pre-heating our make up air ! I believe most of the systems you are talking

about use an external exhaust fan !

There is a National contest to evaluate a new crop of High efficiency Wood burners just starting testing in Washington D.C. NOW, a few will have similar technology, My Bet is

down on a R.M.H./ Masonry Heater Hybrid! Watch this space for further developments !

I went to

www.condexenergy.com/how it works for the information that I am paraphrasing and thus is subject to possible error !

Reading

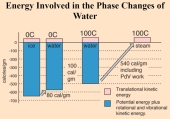

Their graft, it seems o show a nearly flat line below 150 degrees F, which is in the upper range that we find acceptable or R.M.H. Exhaust !

While they claim a 22% savings with a Conventional Fossil Fuel Fired Furnace With a typical exhaust temp of 500 degrees F reduced down to 80 degrees F, at our upper range

of 150 degrees F a drop to 80 degrees will not show that much improvement - we often see condensation occurring within the Horizontal piping of our thermal benches, new

builders are always cautioned to slope the last 10 feet towards the last clean out !

Do we get the latent heat of evaporation constantly at 100% conversion ? No Outside Temps, prevailing wind direction and Barometric Pressure fluctuations will all have their

effect but our system rarely if ever gets out of whack, as compared to The mechanical marvel that my simple google search re-introduced me to !

Again, this is a very promising line of future research for more conventional Wood Stoves, and some day we all may gain from this line of research ! For the Craft ! A. L.

As always your questions and comments are Solicited and Welcome, Think like Fire, Flow like a Gas, Don't be the Marshmallow ! PYRO - Logically, Big AL !

* Have you been to our sister site

richsoil.com ? A.L.

![Filename: Fig1.jpg

Description: [Thumbnail for Fig1.jpg]](/t/27052/a/10430/Fig1.jpg)

![Filename: Fig2.jpg

Description: [Thumbnail for Fig2.jpg]](/t/27052/a/10431/Fig2.jpg)

![Filename: Fig3.jpg

Description: [Thumbnail for Fig3.jpg]](/t/27052/a/10432/Fig3.jpg)

2

2

1

1

1

1

![Filename: Fig4.jpg

Description: [Thumbnail for Fig4.jpg]](/t/27052/a/10568/Fig4.jpg)

1

1

1

1