7

7

8

8

11

11

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

6

6

9

9

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

10

10

6

6

7

7

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

6

6

5

5

9

9

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

9

9

6

6

4

4

6

6

6

6

7

7

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

6

6

6

6

4

4

10

10

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

3

3

6

6

3

3

4

4

4

4

4

4

5

5

Eloise Rock wrote:Cristobal, could you clarify what you mean by raising the riser 10mm?

4

4

4

4

5

5

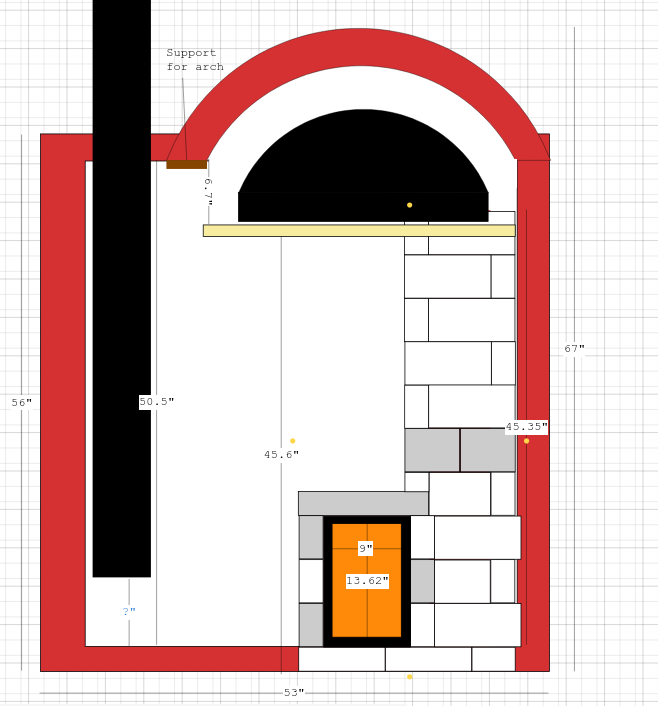

![Filename: Shorty-Stove-Elevation.png

Description: [Thumbnail for Shorty-Stove-Elevation.png]](/t/275976/a/264111/Shorty-Stove-Elevation.png)

6

6

3

3

|

There's a way to do it better - find it. -Edison. A better tiny ad:

New Year, New Earth Summit - register for free!

https://permies.com/t/367268/Year-Earth-Summit-register-free

|