1

1

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

"You must be the change you want to see in the world." "First they ignore you, then they laugh at you, then they fight you, then you win." --Mahatma Gandhi

"Preach the Gospel always, and if necessary, use words." --Francis of Assisi.

"Family farms work when the whole family works the farm." -- Adam Klaus

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

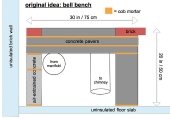

Matt Walker wrote:Max, yours is a special case for sure! I didn't mean to imply you shouldn't do everything you can to seal them. One certainly should seal a system in my opinion. Just wanted to offer a differing opinion of what is going on inside a running system. When starting from cold, which you are always doing since you have no mass Max, they will send gasses out of the leaks, but in my opinion that's due to a "plug" at the end of the system from a cold stack, rather than pressure being developed by the combustion core/radiator combo. As Peter, Donkey, myself, and others have noted, once warm and running the pressures are lower within the system. At any rate, upon further reflection, I think as drawn the friction on this one would be too much drag as R Scott so astutely points out, so it's a moot point anyway.

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

|

Enjoy the full beauty of the english language. Embedded in this tiny ad:

Looking for cold-climate growers to join a GOOF livestream panel (Missoula)

https://permies.com/t/369111/cold-climate-growers-join-GOOF

|