God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

mike Splendid wrote:I am wondering if the riser (the insulated section where secondary burning occurs) can in fact be horizontal?

NO! Riser is vertical. The reason for the riser is that you need something to power the movement of hot gasses through the system. Place your heat riser as early as possible and as high as possible in the system! This will cause a greater sucking action which will in turn suck the maximum air into the system which in turn will cause a more efficient burn and in turn push the exhaust gasses through the system to heat the mass and exit at the intended exit point.

Lets just imagine for a moment that you can do what you want to do...run the fire, heat, gasses horizontally as far as possible...for a good clean burn you will have incredible heat, heat that will eat up most materials including steel. Or you will need very expensive materials that can take the heat as well as an electric fan/motor pushing those hot gasses along.

The idea you are proposing is not one that would be very practical and would be prone to many engineering difficulties. Perhaps there is a way, but (if that way exists) that way would take a great deal of research and costly materials to achieve.

1

1

mike Splendid wrote:.skp viewer

http://www.anycad.net/the-free-skp-file-viewer-skpviewer.html

I still cannot vie that file. Can you post a .jpg?

>but rather use bells.

wassat?

@Michael

I understand. I guess I am not clear why the riser is vertical? I assume because hot air rises and we want that to cause draw, but if that were true then what about the downdraft designs?

So if we can go donw whay cant we go horizontally and let the hot ir rising in the chimney section cause the draw in the system?

Added:

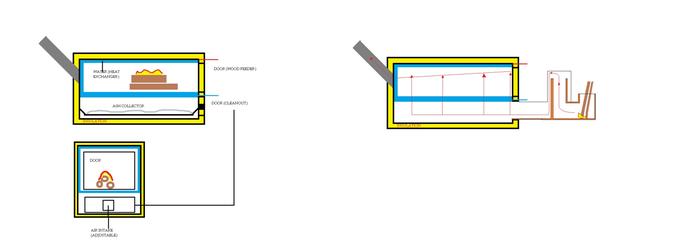

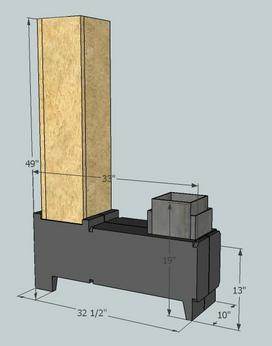

So to go a lkittle further into the logic here, I am heating a 5gal propane tank filled with water (that is slowly circulating under slight pressure from a sump pump)

I DO NOT want 5 gals of hot water perched atop a 5 ft riser. That meas building a large superstructure to hold it al and it ends up looking butt ugly and makes me nervous. I want the propane tank CofG LOW. Really I want it sitting at the end of a horizontal tunnel and for it to be the base of a chimney that encloses it.

The next part is that while I could cut and grind for week and whip out the MIG, I want to do this in a few hours with some fire bricks on the ground. Simple. Easy. Love it! So Really I want a long tunnel that is part firebox and part "riser". My idea is to run a number of smalled metal tubes into the "riser through the firebox to provide more air for the secondary burn. This will heat the air on the way through the firebox and its easy to lay some lengths of metal pipe at the base of the tunnel protruding out.

I am just not sure about the functioning of the "riser" portion of the tunnel.

www.dragonheaters.com

http://blog.dragonheaters.com/

Michael Skowronski wrote:The idea you are proposing is not one that would be very practical and would be prone to many engineering difficulties. Perhaps there is a way, but (if that way exists) that way would take a great deal of research and costly materials to achieve.

mike Splendid wrote:This is the bell?

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

1

1

I may wrap the bricks in fibreglass roof insulation tomorow.

www.dragonheaters.com

http://blog.dragonheaters.com/

www.dragonheaters.com

http://blog.dragonheaters.com/

1

1

If I layed it on the ground so the riser was horizontal and added a chimney, would it still work as well?

www.dragonheaters.com

http://blog.dragonheaters.com/

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

What physics allows pushing the heat back down without penalty to (canceling out) the draw?mike Splendid wrote:>Are you trying to heat living quarters or water?

A Small pool.

Yes I take your point about fighting physics. Perhaps the way to do this is to go up and then come down in another vermiculite board tunnel before entering the heat exchanger i Have built. ie no 55gal drum. contain the neat on the way back down... so wait, does that mean I could use a riser that is half as high?

Perhaps on our part...(definitely me)...not a complete understanding of your goals.

So, perhaps take what has been offered and build a working model to your specification next to "known working models" and compare..

yet hope to post soon a dialogue on the traditional systems mentioned

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

|

I carry this gun in case a vending machine doesn't give me my fritos. This gun and this tiny ad:

Learn Permaculture through a little hard work

https://wheaton-labs.com/bootcamp

|