1

1

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

1

1

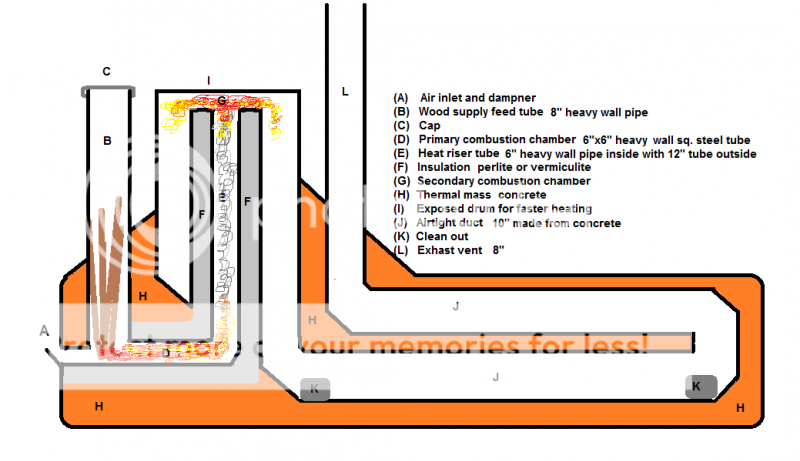

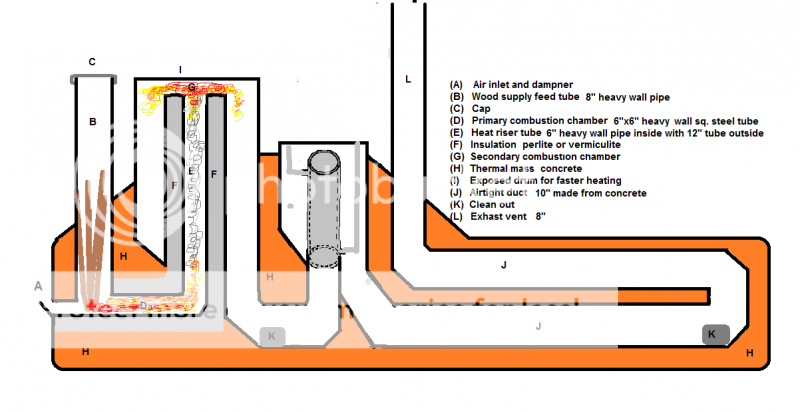

Rick Lawrence wrote:Hi all newbee here,

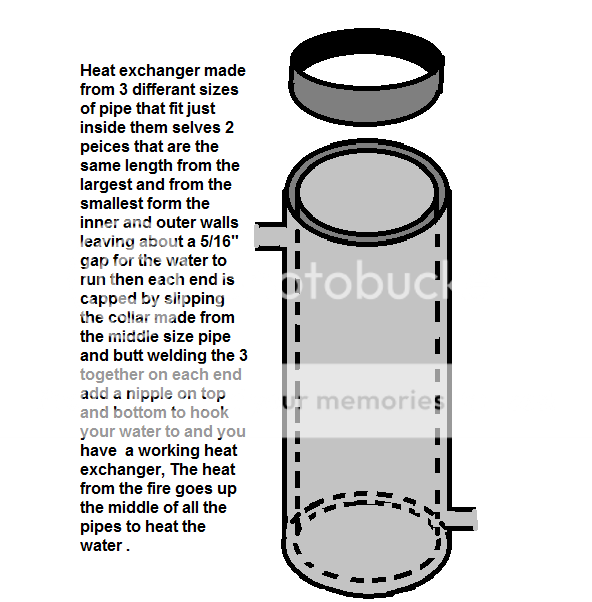

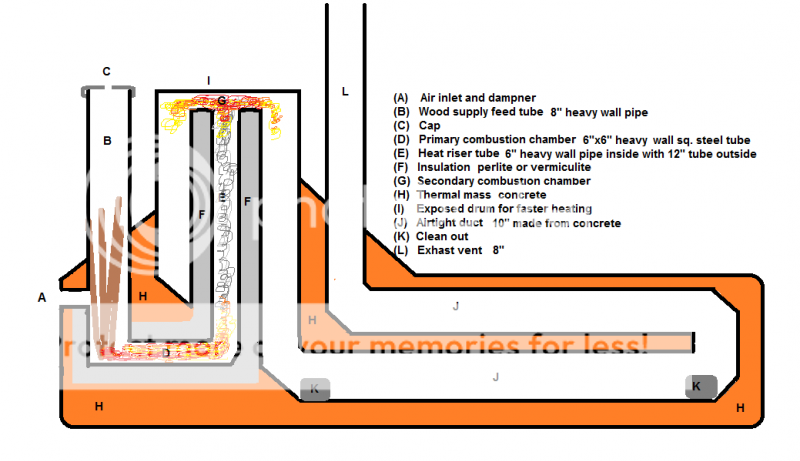

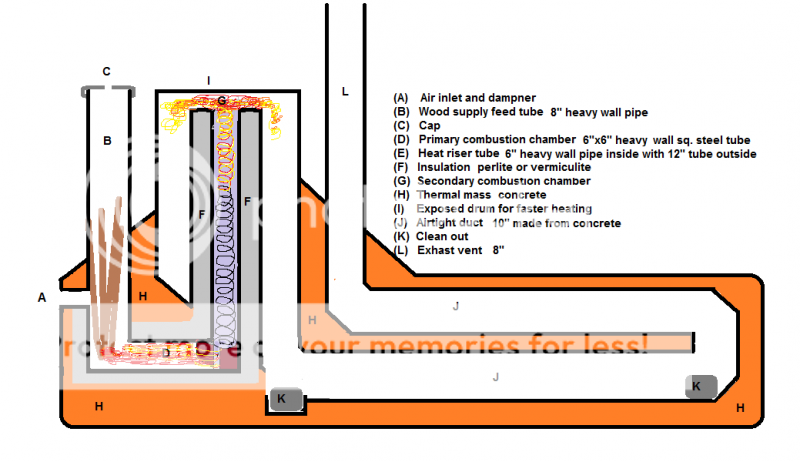

Looking for info and help on a rocket mass heater for my house I'm going to build next summer. I want to have a stove to heat a 1500 sq. ft. home in N. Idaho where it can get very cold at times. I want to to be somewhat self feeding and self temperature regulating. I have a basic plan of what I want and I want to made the main fire components out of heavy wall steel tubing and pipe, and the thermal mass out of concrete and some kind of filler. I have drawn up some plans that I'd like some opinions on. What is a good idea here and whats bad, I want to make the air intake open and close with a thermostat to regulate the house temperature in the winter. I'm also thinking of adding a pipe in a pipe heat exchanger to preheat the water going into my tank-less hot water system. But not sure how to add that to my current plan. I have seen some guys make a hot water heater by replacing the heat riser tube with the pipe in a pipe heat exchanger but i think that would cool the smoke in the secondary combustion chamber to much to get a good burn of all the remaining gases. Could I add a second heat riser tube to do this and then through the thermal mass? I plan to cover all the concrete in river rock to make it pleasing to the eye as well and make a reclining bench out of the thermal mass over the J duct work that will be covered with cushions like a couch. What needs to be done to the floor to hold up this kind of weight. I'm putting this into an addition to my current home that I have not started it yet, so I can build it as it needs. So any thoughts???

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

1

1

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Arlyn Gale wrote:According to my new friend - http://www.pagetutor.com/octagon_layout/ , you'd have to trim the outside tips of 2" brick a bit to fit into a 10" pipe. (Perfect cuts would require a minimum 10.75" ID pipe with untrimmed 2" bricks). From everything I've read, metal should hold up OK on the outside of the heat riser.

allen lumley wrote:Speaking as an old cheapskate, I have no problems with building an RMH with what comes to hand, Ideally the floor of the combustion core should have

some hard dense fire brick for durability,and a case can be made for including them in the heat riser to promote a good strong draft and easy relighting

Having said that the less mass to absorb the heat the more of the heat energy that will be reflected back into the combustion zone, the quicker it will come

up to temperature and the Cleaner the total burn will be!

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

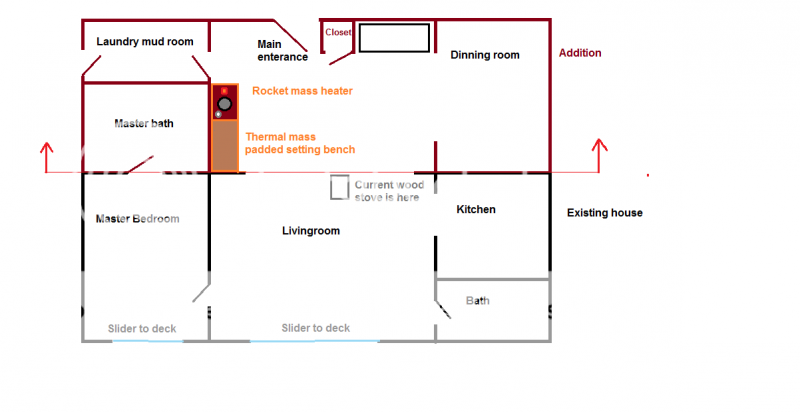

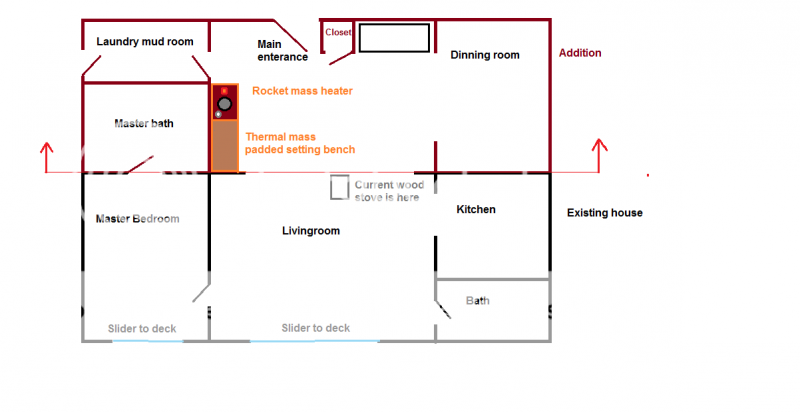

Rick Lawrence wrote:Ok, tnx to all that have replied to my post. First off here is my addition plans. The new rocket stove is as close to the center of the completed house as I can get it and keep my floor plan.

The addition is going to double the current house size. so everything above the red line will be new.

Second I don't understand why heavy walled steel tube would fail, when I see tons of rocket stoves made from basic stove pipe on the net?

I'm talking about 3/8 " wall steel here. Even at 1000 deg it will still hold up fine. I've been a welder and steel fabricator all my live so i have some knowledge of steel melting points and such. Granted I have never built a rocket stove so I don't claim to know it all, just trying to understand the whys. I want a stove that will burn for at least 8 hours that's why the long feed tube so I can stick a larger amount of wood in it and it would gravity feed into the burn chamber. I do not want to just sit and tend a fire all day just to keep the house warm. Somebody must have figured out how to do this. I have read a lot and I see a lot of different ideas on the best way to build a rocket mass stove and I'm hoping to find a happy medium. I do plan to build some small test stoves to work out some of my ideas over the rest of the winter to see what works and what doesn't.

One last thing I don't have any source of natural clay here that is why I was doing to use the concrete and I want to make it all look like river rock when done.

Arlyn Gale wrote:[quote=Rick Lawrence "Did you read my post at all? Like it says 2" firebrick cut at 22 1/2 degrees 3 7/8" long."

If you cut 2" bricks per your diagram, they won't fit in a 10" pipe without further trimming, and, perhaps more importantly, will only give you a 5-3/8" (inside) octagon.

[/b]For a 6" (inside) octagon, 2" brick should be cut (@22.5*) 4-1/8"(long) [/b]. The outer octagon would be 10".

allen lumley wrote:

Late note : Rick, while probably not idea you can create an interesting spiral to stagger your mortar joint lines, this will increase turbulence and may or may not help

complete combustion ! A.L.

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

1

1

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Arlyn Gale wrote:Allen - yes, the staggered mortar joint makes the alternate courses interesting. A square outside/octagon inside, such as PvdB documents, addresses that issue.

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

allen lumley wrote:Rick Lawrence :I find that I like your idea a lot,

I hope you have a little more extra slop in your 10 inch pipe then is shown in your sketch, or can trim a little thinner, Your Firebrick will expand ! Some room for

expansion must be allowed for !

Rick Lawrence wrote:

allen lumley wrote:Rick Lawrence :I find that I like your idea a lot,

I hope you have a little more extra slop in your 10 inch pipe then is shown in your sketch, or can trim a little thinner, Your Firebrick will expand ! Some room for

expansion must be allowed for !

Hey Allen,

AKA Big Al

Do you think that firebrick expands more then steel when hot? They will both expand some I know and for the most part, the steel will be at a lower working temperature than the firebrick will be so I'm not really sure how it will effect it. I may modify my idea to use thinner firebrick as somebody suggested and more insulation on the outside to cushion the brick as it expands.

allen lumley wrote: I understand that you want to try a feed tube '' B '' that is much closer to equal in length to the height of the Heat Riser " F ", this has been attempted many times,

the working height of the Feed Tube " B " will always create Smoke back and flames burning up the wood when it exceeds 1/4 of the height of the Heat Riser " F "

unless the system is modified to run constantly as a forced draft system, this isolates the Feed tube and makes by ear adjustments of the air fuel mix impossible

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

1

1

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

![Filename: 20150105_184524.jpg

Description: [Thumbnail for 20150105_184524.jpg]](/t/42883/a/25312/20150105_184524.jpg)

Daves Hobbit Home Build progress

@undergroundandlovinit

|

We've gotta get close enough to that helmet to pull the choke on it's engine and flood his mind! Or, we could just read this tiny ad:

Large Lot for Sale Inside an Established Permaculture Community — Bejuco, Costa Rica

https://permies.com/t/366607/Large-Lot-Sale-Established-Permaculture

|