Daves Hobbit Home Build progress

@undergroundandlovinit

"You must be the change you want to see in the world." "First they ignore you, then they laugh at you, then they fight you, then you win." --Mahatma Gandhi

"Preach the Gospel always, and if necessary, use words." --Francis of Assisi.

"Family farms work when the whole family works the farm." -- Adam Klaus

R Scott wrote:Clean outs don't need to be 45's like sewer lines. Standard Tees would be much easier to hide the port in the floor.

You are going to have problems not having the final pump of the chimney passing next to the barrel. Your exhaust could get too cold to rise.

shilo kinarty wrote:you need good insulation under the horizontal part and around the vertical chimney

Glenn Herbert wrote:It looks like you are preparing for a chimney brush to scrape out all surfaces of the ducting. . . . Experience will show you how often various parts need to be cleaned..

Glenn Herbert wrote:

What is the total length of your underfloor run? That may be an issue depending on the size of the house. 8" is said to be good for up to 50' of horizontal (minus 5' for each elbow, which you don't have any of.)

Glenn Herbert wrote:

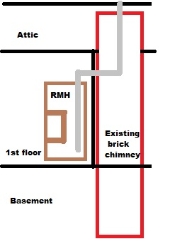

The chimney will work better rising inside and elbowing out the wall top, assuming you have a colder climate, regardless of code requirements for woodstoves. Remember that this is not a woodstove, it is more like a masonry heater. Also, you could reasonably describe the elbow rising out of the slab as the exit from the heater; then you have a situation identical to many woodstoves of one 90 going out the wall and one to go up the chimney.

Daves Hobbit Home Build progress

@undergroundandlovinit

I kinda like the idea of going outside - in a insulated concrete block - and not loose space inside the home . . with the chimney inside, I would loose square footage - floor too ceiling.

Glenn Herbert wrote:Actually, with the extreme insulation of 8" of styrofoam around the outside, if the chimney block is integral with the house wall, it might as well be inside - it will be much closer in temp to the inside than outside regardless of fire.

Daves Hobbit Home Build progress

@undergroundandlovinit

Dave Lot wrote:

Glenn Herbert wrote:Actually, with the extreme insulation of 8" of styrofoam around the outside, if the chimney block is integral with the house wall, it might as well be inside - it will be much closer in temp to the inside than outside regardless of fire.

Have the chimney inside, but pour a concrete block around it ? Not a bad idea, insurance can't say it's a fire hazard (encased in concrete) I would still loose some space, but it would keep things warm . .

Daves Hobbit Home Build progress

@undergroundandlovinit

Glenn Herbert wrote:One thing I would be concerned about regarding styrofoam insulation is that parts of the concrete between the duct and the styrofoam will have nowhere to dissipate heat. The heat in that zone will eventually build up to close to the gas temperature in the duct, which near the fire will be several hundred degrees. I fear that the styrofoam in those concealed spaces will melt (very likely) and maybe even ignite if air can get to it (unlikely).

The only safe solution to heat buildup is to allow airflow to carry away excess heat. This would let the heat from that section become useful instead of simply conducting slowly into the ground.

Daves Hobbit Home Build progress

@undergroundandlovinit

Glenn Herbert wrote:Perlite-clay can be mixed very sparse on the clay and be very insulative, especialy in a contained space such as under a slab where it doesn't have much difficulty maintaining its shape. My guess would be that a simple layer of 8-10" of perlite-clay under the duct and to its sides would be close to the styrofoam insulation value and be totally heatproof.

I have mixed perlite-clay by the method of misting perlite with water, dusting fireclay on and mixing, repeating until all the perlite has a thin coating of clay. That made a heat riser fill that was strong enough after firing to resist handling and moving in a car several times.

![Filename: under-slab-rocket.png

Description: [Thumbnail for under-slab-rocket.png]](/t/44706/a/33800/under-slab-rocket.png)

Daves Hobbit Home Build progress

@undergroundandlovinit

| I agree. Here's the link: http://stoves2.com |