![Filename: rocket-stove.jpg

Description: [Thumbnail for rocket-stove.jpg]](/t/52684/a/35145/rocket-stove.jpg)

How permies.com works

What is a Mother Tree ?

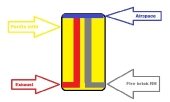

Burra Maluca wrote:What are the tubes made of? Metal is going to burn out at the temperatures a rocket stove will reach.

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

1

1

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

1

1

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

1

1

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

![Filename: rocket-stove-design.jpg

Description: [Thumbnail for rocket-stove-design.jpg]](/t/52684/a/35230/rocket-stove-design.jpg)

, When a new future Rocketeer shows up here we want to make sure that he has the best information possible, its easier on everyone

, When a new future Rocketeer shows up here we want to make sure that he has the best information possible, its easier on everyone

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

|

They kept fire breathing monkeys as pets! This tiny ad told me so!

Rocket mass heaters in greenhouses can be tricky - these plans make them easy:

Wet Tolerant Rocket Mass Heater in a Greenhouse Plans

|