Silence is Golden

For all your RMH needs:

dragontechrmh.com

1

1

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

2

2

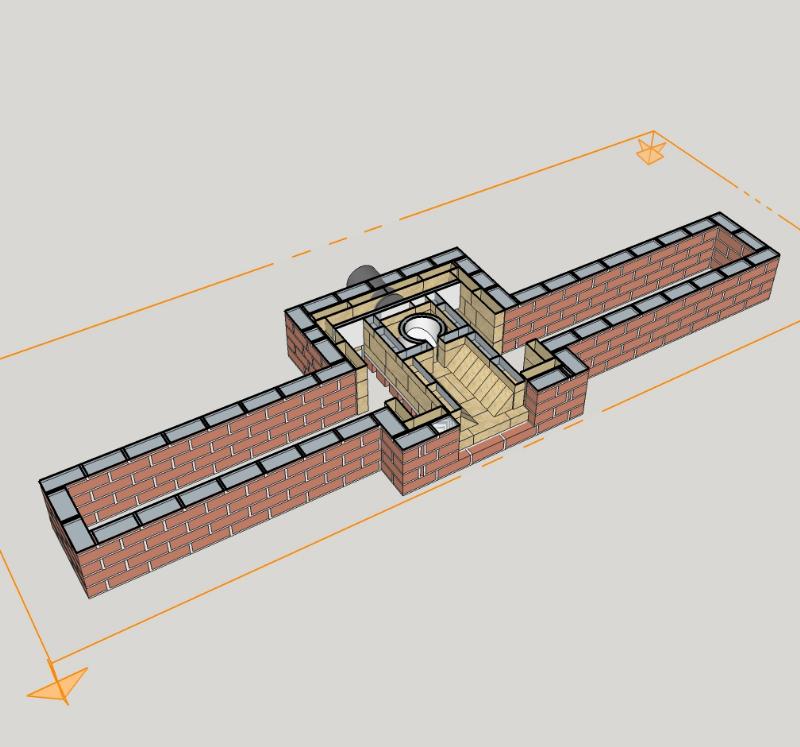

Gerry Parent wrote:1)I am wondering about the words "almost to the floor". My exhaust pipe comes straight down into the bell and was wondering how close to the floor of the bell it should be? See "bell 1" picture.... the brick and shim are only there temporarily to hold up the 6 inch diameter pipe which is about 6 inches off the floor. Would adding a funnel on the end of the pipe help channel the cool gasses into the pipe easier or not worth the effort?

Gerry Parent wrote:1)2) At what point do columns or other mass inside the bell become a drag on the gas flow (if at all)? Is there a general rule of thumb to follow or is it a calculated percentage of the volume of the bell?

regards, Peter

The "plunger tube" you are using, needs to have a gap from the floor, of at least system CSA. But, if the cooled gasses can't enter from all around at the same time, with a wall nearby or else. 2 or 3 times CSA is better.

It works the same as top gap or hear riser gap. Tho, cooled down gases are slower, denser, and if hotter than ambient, they tend to rise naturally, creating a depression at the mouth of the plunger tube, so no need to make the gap too big.

A good trick i like, fit two tubes of the same diameter in each others, cutting one up, to allow insertion into the other. (rivet it's two lips so it holds by friction in the other) So you can push it up or down, to fine tune your system.

Silence is Golden

For all your RMH needs:

dragontechrmh.com

The way you have situated the plunger pipe means one side isn't very effective in exhausting because there's a wall close by (or so it seems).

Silence is Golden

For all your RMH needs:

dragontechrmh.com

I'm not sure what you mean by creating a depression? I imagining the gases wearing away a little crater just below the opening of the exhaust tube on the floor of the bell. I'm pretty sure this is not what you mean and wondering if you could elaborate a bit further please.

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Silence is Golden

For all your RMH needs:

dragontechrmh.com

Gerry Parent wrote:

One extra question: Does the drop tube need to be insulated or can it be just left bare?

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Silence is Golden

For all your RMH needs:

dragontechrmh.com

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Silence is Golden

For all your RMH needs:

dragontechrmh.com

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Silence is Golden

For all your RMH needs:

dragontechrmh.com

Silence is Golden

For all your RMH needs:

dragontechrmh.com

1

1

Gerry Parent wrote:So what your saying is there is no optimal height for it to be so just plunk it somewhere lets say between half way and the top and experiment to give the best results for each particular system?

Another question..... Does it matter the shape? For instance, as we're interested in stratification (and not trying to disturb it as much as possible), would it be better to make a more oval or even horizontal rectangle as the opening as long as it maintains system CSA?

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

The shape of entrance, and exit are better shallow and wide. Tho, remember, anything less than 2.5 inch in height, you will have to widen more than CSA, to counteract the effect of the boundary layer. Furthermore, even before this limit, you have to care for the fact that gases travel slower at the very floor level. That they have to turn two edges to enter the chimney. So Peter says 2 to 3 times CSA is better.

One side note. The shape of the bell can be important too.

Silence is Golden

For all your RMH needs:

dragontechrmh.com

Satamax Antone wrote:

Well, what i'm saying, is that we know the best bell design. Low entrance, low exit, tall, with enough internal surface area, and enough mass.

Jason Durrie wrote:

Satamax Antone wrote:

Well, what i'm saying, is that we know the best bell design. Low entrance, low exit, tall, with enough internal surface area, and enough mass.

I'm surprised by the recommendation to have a low entrance. If stratification of the gases in the bell is the objective, then the entrance should be high (and lowest velocity possible) to minimize mixing of the stratification layers. Is there some other reason to locate the entrance low?

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Silence is Golden

For all your RMH needs:

dragontechrmh.com

Gerry, plunger tube is another story. Since it's metal, it heats up, and in turn reheating the gases which travel through it, giving a suction effect.

If the former, you insulate, so you don't lose energy to reheat already cooled gases. As long as they are hotter than ambient, and sufficient to keep themselves moving fast enough for the heater. Fine.

Silence is Golden

For all your RMH needs:

dragontechrmh.com

Satamax Antone wrote:Gerry, plunger tube is another story. Since it's metal, it heats up, and in turn reheating the gases which travel through it,

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Silence is Golden

For all your RMH needs:

dragontechrmh.com

Silence is Golden

For all your RMH needs:

dragontechrmh.com

Silence is Golden

For all your RMH needs:

dragontechrmh.com

Peter van den Berg wrote:

Good question! The workings of a bell relies on the difference in volume between the exhaust (and inlet) pipe and the bell. To see what the difference is, take a cross section area of the bell/bench where a column is and compare it to the csa of the exhaust. The resulting figure should be at least 5 times the pipe's csa, preferably more. In other words: the smaller the bell, the less the gases are able to slow down and stratify, separating the hotter form the colder gases. One column every 4 feet won't affect the bell's aerodynamics much, but every 1 foot does.

1

1

regards, Peter

Peter van den Berg wrote:A dead end bench of that size would work, provided it is constructed as shown on the website.

Kelly Pridgen wrote:I like the concept of using a plunger tube made with brick in one corner of the bell. The key would be in making the opening as low to the floor as possible in order for the dead-end bench (I'm only making one) to function properly. I believe this would negate the need for the baffle board. Is my thinking correct?

regards, Peter

Kelly Pridgen wrote:Thanks, Peter.

A couple more questions on using a plunger tube made of brick inside the bell.

1. Does the external surface area of the brick plunger tube count towards the total ISA of the bell?

Kelly Pridgen wrote:2. I'd prefer to keep it simple with a 8" square plunger tube (for 8" batchbox). Hope square is ok. I understand the factors that make a round (or octagon) shape better in the riser, but do they apply for the plunger tube?

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Kelly Pridgen wrote:1. Does the external surface area of the brick plunger tube count towards the total ISA of the bell?

Kelly Pridgen wrote:2. I'd prefer to keep it simple with a 8" square plunger tube (for 8" batchbox). Hope square is ok. I understand the factors that make a round (or octagon) shape better in the riser, but do they apply for the plunger tube?

regards, Peter

|

You don't like waffles? Well, do you like this tiny ad?

Rocket mass heaters in greenhouses can be tricky - these plans make them easy:

Wet Tolerant Rocket Mass Heater in a Greenhouse Plans

|