1

1

1

1

1

1

1

1

Need more info?

www.earthenhand.com

Earthen Hand Natural Building

"If everyone makes a difference, the world will be different."

earthenhand wrote:

Very good testing. Thank you.

I believe this technique is called 'isochanvre' in France and goes way back, actually.

Also, I heard of a woman who built a house out of hempstalks she grew on site. She planted them in a circle and waited. She also planted extras. Then she bent them into a dome, tied them together, wove other hurds horizontally, and then plastered the whole thing with lime-crete. Beautiful! Sorry I couldn't find the link for that one. She was in the USA.

Cheers,

Need more info?

www.earthenhand.com

Earthen Hand Natural Building

"If everyone makes a difference, the world will be different."

1

1

klorinth wrote:

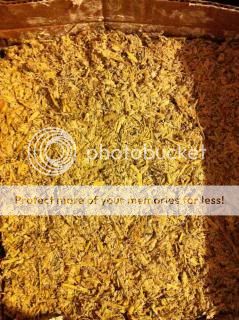

...But in this application the goal is a material that gives insulation as well as mass. For that you need the hurds.

...

wormilicious wrote:

Sorry for asking a dumb question, but where the heck do you get hemp hurds from?

I was thinking about insulating my outdoor worm hopper with mud plaster. Sounds like this would work as well and be more durable, as it's made from lime.

. I think it's more a case of doping your organic matter with concrete than doping your concrete with organic matter. I would think that keeping it dry would be of the utmost importance however. I hear papercrete molds something fierce.

. I think it's more a case of doping your organic matter with concrete than doping your concrete with organic matter. I would think that keeping it dry would be of the utmost importance however. I hear papercrete molds something fierce.

pubwvj wrote:

I would suggest avoiding putting organic fibers into concrete. If you must, please do long term trials before you build anything serious with it... For your own sake.

steveowen wrote:

Hello all,

Do you think hempcrete would work in hyperadobe-style tubes? I was thinking post and beam frame with 'cretebag walls. Is it affordable?

Thanks!

|

Check your pockets for water buffalo. You might need to use this tiny ad until you locate a water buffalo:

Looking for cold-climate growers to join a GOOF livestream panel (Missoula)

https://permies.com/t/369111/cold-climate-growers-join-GOOF

|