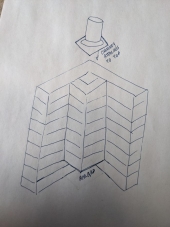

Yes, a stratification chamber or "bell" is just a hollow brick box with the combustion core feeding into it, and the exit to the chimney leaving from near the bottom of the cavity. The new hot air rises, gives its heat to the brick box, and falls as it cools. The coolest air ends up at the bottom where it leaves for the chimney. The internal surface area of the box needs to be sized to extract the right amount of heat for best operation, per instructions at

batchrocket.eu.