Thanks Thomas & Satamax !

There´s a guy with the nick Manuel over at Donkey's who had the same idea independently and

uses it in his builds, but he cuts the pipes by eyeball, which is ok when he cobs them in.

Cutout template rolled around the barrel is 44 cm / 17.5 " wide and 15 cm/ 6" (system size) high, circumference/edge length approx 1 meter / 3.3 feet.

More important to me was the intersection depth that is 11 cm / 4 1/3 " (depth 0 means tubes touch but do not intersect).

The nicest thing about this I discovered: when you open the cleanout you can see straight through to the bench entrance an clean super easy if necessary.

And since the combustion unit is mobile you can hook up the thermal battery left or right depending on where you install it.

The build sequence isn´t published yet, I plan to do so here and at Donkey's, but it will take some time. I want to run the stove for some time and get used to fire it under all atmospheric conditions before I declare success.

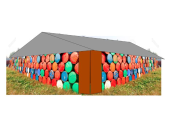

Here´s a pic of the finished unit. Flue pipe ends sticking out behind the barrel to the left and right not visible here: