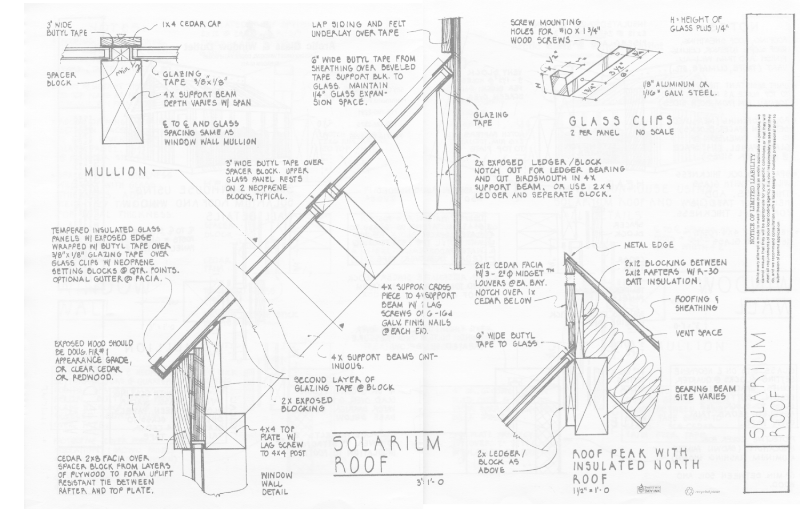

Pearl Sutton wrote:I was interested in the picture James Victor posted, it was hard to read... Too much caffeine on an off day, I redid the text to make it legible. Can someone look at it and see what the bits of red text are? I'm uncertain of those... some E looking things that look like a specialized symbol (edge to edge maybe?) and 6 inch butyl tape? I see no such thing on line for sale, not sure I have that right.

As far as the drawing itself, wow. That dude has a much higher budget for butyl tape than I do. And uses a LOT of the stuff. Not sure about a lot of it for my own use, but it is an interesting reference diagram.

Kari Gunnlaugsson wrote: When i hear you say 'shanty boat' i'm imagining a barge or maybe a scow hull, is that right? Sheltered waters, not much moving around? Towed or under power, but not sailing? I guess my main concern would be that what the boat needs to function as a boat comes first, and if a stove can fit within those parameters then carry on. It seems like it would be hard to get the weight very low in the hull as the heater is going to need a certain amount of vertical height to function and if you want it as a bench it's already above the sole..........