Hello Fellow Permies! Great News up here in the Canadian PNW!

“Frankenstove 6” has begun fabrication. I have been given the Grace of my Wonderful Wife Patti to shift some of the items on the Home Job List and I will be posting the progress of the build as I go! I will try to keep the construction simple by using basic tools such as a drill, grinder, welder and hand tools. This project will use extensive welding to create a Vertical Thermal Mass Rocket Stove that will be used in an 8’x12’ greenhouse that is built over a 8’ diameter aquaponic pond to grow food like lettuce kale and arugula.

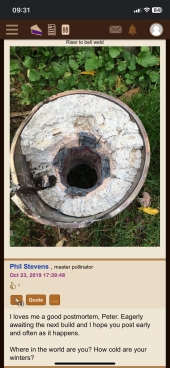

The main materials will be one 100 lb propane cylinder, one 30 pound cylinder, some square tubing, ceramic tubing and refractory cement and an aluminum toolbox! Yes! This will have the general look of the F5, but much more compact to fit in the greenhouse. Of course, it will be wood pellet fed and of course, not require any electricity to operate. I know my design strays wildly from the grassroots style of rocket mass heaters on this sight but it’s design may inspire others to push the envelope when the decide to build ther own! I should also like to continue with the 4” diameter riser that has operated in Frankenstove Models 3, 4, and our current operational Frankenstove 5. So without further ado, here are some pictures of the start of the build. Stay tuned, be safe, be warm, be Kind!