William Bronson wrote: I'm gonna throw this out there.

Use RapidSet CementAll as the cement portion and an aluminum oxide or garnet blasting sand as your aggregate.

Add handfuls of rockwool into the mix to resist cracking.

Now use it wherever you like, heat be damned, and you should be fine.

I've used this mix, plus perlite to form the feed, burn tunnel and riser on a j tube rocket stove.

It's very durable, resistant to heat an physically strong.

The addition of perlite makes it physically weaker,not strong enough to support weight over a large span, but insulative and easily worked with saws and drills.

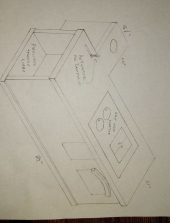

My under construction batch box is made of slabs of this mix.

I left out the aluminum oxide sand, they seemed superfluous.

RapidSet CementAll isn't officially a refractory cement.

It is an Calcium aluminate cement, rated to 2300 degrees in at least one official msds document,and about $20.00 a bag Vs. 50 bucks for "real" refractory cement.

It sets up crazy fast which is either a bug or a feature...

With all that said, I have also had great luck with cob and/or soil cement over steel mesh, wires shelves, or sheet metal.

I recommend screwing some hardware cloth to the sheet metal to create a bond.

I plan on topping some of my own bells with aluminum sheet pans from the scrap yard, filled with a CementAll mix, topped with soil.

I want to be able to get back into the bell for inspection, and each of these will form a large access panel.