Samuel Plante wrote:

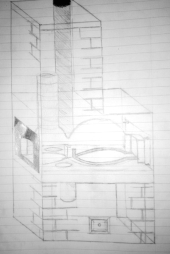

So I've been thinking about this since mid-winter, about the idea of putting a Double chamber oven which is inpired by Ernie and Erica's ''Double chamber cob oven'' into a masonry bell.

The bell would be divided into three floors.

Floor number one is the bottom cleanout area and the non-bypassed chimney exit. In front of the lowest stove pipe opening would be a small cleanout door that would serve as a way to prime the chimney (not pictured). A simple bell made of masonry.

The second floor is basically the oven level with two or four holes made in a support slab, through which the gases would flow downwards. This part of the bell, has it's void filled with uncompressed rockwool.

Thirdly, there is the riser chamber, possibly an insulated bypass exit could be present above the heat riser so the stove could be used in summer. The stove pipe exiting through the roof could also be wrapped in insulation to minimise heat transfer through the building (also not pictured).

The core parts for the oven would be cast dense refractory concrete. I am guessing that it could be done WAY simpler than the drawing with the port à la batch and the fancy secondary air inconel tube.The whole oven mass would be surrounded by a 2 inch thick layer of ceramic wool, followed by rockwool which would fill all the void of the 2nd level, to further minimize heat transfer from the core, to the masonry.

As I mentionned in the title, this is purely an imaginary thought, a concept of a mix between a ''van den Berg style batch box'' and a ''Double chamber cob oven''. An indoors masonry bell oven that could used in the summer time.. The two doors would be insulated as well, at least for the summer time. Mounted on rather large steel plates, both of which would be removable so we could access the riser and the chimney parts. The steel plates themselves would serve as an immediate heat source (I'm thinking right now that we could have a set of glass doors that would also serve as an additional heat source in the winter).

There could be a third door on the third floor, leading to a white oven.

I'm looking forward to sharing ideas with you all!

Good night.

The whole oven mass would be surrounded by a 2 inch thick layer of ceramic wool, followed by rockwool which would fill all the void of the 2nd level, to further minimize heat transfer from the core, to the masonry.

The whole oven mass would be surrounded by a 2 inch thick layer of ceramic wool, followed by rockwool which would fill all the void of the 2nd level, to further minimize heat transfer from the core, to the masonry.

Steve Shelton wrote:The metal rod I used was salvaged from a section of cattle panel fence. They were about 1/4" thick or possibly less. The final thickness of the roof pieces should be 2" or more. Imbed the rods in the middle of that 2" thickness.

I suggest you test whatever mixture you come up with prior to your final pour. I went through many component variations before settling on the formula that I used. What you are thinking about trying might be better or it might be worse. The testing process was very time consuming.

Steve Shelton wrote:A few suggestions:

- make the roof of your firebox several inches thick. Geopolymer needs to be cured by fire to reach full tensile strength.

- metal rods can be imbedded into the geopolymer to help with spanning the roof section until the geopolymer is fully cured.

- geopolymer can be easily cut after the initial drying phase. The riser can be made from dry flat sheets that are angle-cut to make the octagon riser.

- the 2 angled floor pieces can be made in the same manner.

- when possible, smaller pieces are easier to work with. Sometimes this is not an option.

- you can make flat molds, once dried, can be cut into the smaller pieces for assembly. The dried pieces can be cut into precise sizes.

- there is considerable shrinkage in the initial drying phase.

Keep me posted on your progress.