Carbon Negative Mass Heaters

This is a summary of Alan Booker's excellent webinar on the topic, found here:

https://permies.com/wiki/204703/Carbon-Negative-Mass-Heaters

Quoted text is taken directly from Alan's presentation material.

A lot of discussion in the green building arena has moved towards zero combustion and full electrification as the ultimate goal. However, a specific type of biomass combustion system actually turns out to be a superior option in a sizable number of cases.

A Carbon Negative Mass Heater is a complete building heating system that integrates a high-efficiency biomass combustion core with a thermal mass to create a heating system that provides net sequestration of Carbon, removing more from the atmosphere than it releases.

First, some groundwork and definitions so we can know we're all talking about the same thing.

One must take into account where carbon exists in our biosphere. There is no new carbon - it just moves around and takes new forms.

Static vs Dynamic Carbon Sequestration

Dynamic Sequestration occurs when Carbon becomes involved in a life process that keeps it out of the atmosphere during the period the Carbon is involved in that process. Typically, some Carbon atoms are leaving as others are joining, but the net total Carbon sequestered is either constant or expanding while the life process continues.

Static Sequestration occurs when a chemical or mechanical process locks up Carbon in a chemically stable form/location where it will not react and return to the atmosphere

Fossil Fuel Carbon Release

The wide-spread combustion of fossil fuels is releasing Carbon that was statically sequestered in the Earth and turning it into Carbon dioxide, raising levels from around 270 ppm before industrialization to over 400 ppm today.

Burning one ton of coal can release over two tons of Carbon dioxide due to the Carbon combining with Oxygen from the Atmosphere.

Now consider the Carbon cycle of a tree. While a tree will contribute to atmospheric carbon by combustion, processing, and decomposition, it also fixes atmospheric Carbon through photosynthesis, storing Carbon in its above-ground and below-ground biomass.

If we replace fossil fuel with responsibly harvested wood biomass as our energy source (in this context, our fuel used for heat), we have a closed carbon loop.

How Biomass Combustion can be Carbon Negative:

Burning biomass will return only part of the Carbon sequestered during the growth process to the atmosphere.

Carbon is dynamically sequestered by:

• The leaves and woody biomass falling to the ground that are decomposed by saprophytic organisms, sequestering a percentage of the Carbon and releasing the rest back to the atmosphere.

• The root exudates feeding the soil food web, which in turn builds Soil Organic Matter (SOM).

• The remaining living biomass of the tree, if it is managed via coppicing or pruning instead of dead-felled.

System Components for the Carbon Negative Operation of a Biomass Combustion Mass Heater

1. On-Site or Local Regenerative Biomass Production

Regenerative biomass production that builds Soil Organic Matter (SOM) is the key to making the system Carbon negative. Keeping production on-site or hyper-local eliminates embodied energy of transport and the problem of cutting ecologically important forests for biomass.

Production options include:

• Coppice

• Pruning

• Storm-fall harvest

• Regenerative forest

management

2. High-Performance Building Envelope

An energy-efficient building greatly reduces the amount of

energy required for heating and reduces fuel requirements,

therefore reducing emissions. Reduction of uncontrolled

drafts increases building comfort.

Strategies include:

• Insulation

• Green Roofs

• Passive Solar

• Thermal Mass & Thermal Inertia

3. Make-Up Air & IAQ Management System

A combustion heat system needs a low-resistance source of air for efficient operation. Many manufactured approaches use a fresh-air vent coming from outside, but certain high-efficiency combustion cores function better using room air. If this is the case, a source of make-up air is needed to replace what is being used by the heater. Whatever the solution, it needs to maintain a high Indoor Air Quality (IAQ).

This includes, but is not limited to, a Rocket Mass Heater.

4. High-Efficiency Combustion Core

The heart of the system is a high-efficiency combustion core that is at least 90% efficient in combusting the fuel.

5. Immediate Radiant Heat Emitter

The system should have a means of providing immediate radiant heat to warm the space while the heater is burning. The percentage of heat radiated immediately versus stored in the thermal mass for release over the following 24 hours should be balanced to immediately warm the space to a comfortable temperature during the same period of time it takes to charge the thermal mass to keep the space warm until the next burn.

6. Thermal Mass Storage

The system should have a thermal mass with adequate capacity to store enough heat to maintain the space at a comfortable temperature for 24 hours.

7. Passive Exhaust System

The system should exhaust to the outside passively through a chimney system, not requiring a fan or other active components.

8. Long-Burn Operation Cycle

Since the dirtiest parts of the burn happen during start-up and burn completion, the ideal is to maximize clean burn time versus start-up and shut-down time. To do this, the operational cycle should ideally be designed to be a single long burn each day, with the thermal mass carrying the system over to the next day’s burn.

System Attributes:

• Clean Combustion and Low Emissions

• High Combustion Efficiency

• High Heat Retention and Use

• Low Embodied Energy

• Low Embodied Pollution

• Low Embodied Carbon

• Dynamically Sequesters Carbon

• Cleanest Whole-System Footprint

• Biophilic

Embodied Energy is defined as the energy used to produce a product, including the energy needed to:

• Extract/mine, process, and transport raw materials

• Manufacture and ship sub-assemblies

• Manufacture, pack, ship, and deliver the final product.

Embodied Pollution is defined as the amount of pollution created as a byproduct of manufacturing, packaging, shipping, and installing a product.

Embodied Carbon is defined as the amount of Carbon released into the atmosphere as a byproduct of a product’s manufacture, packaging, transport, and installation.

A Carbon Negative Mass Heater has a radically smaller whole- systems footprint than any of the alternatives when you conduct a source-to-sink analysis. Any system that uses off-site generated energy must include the amortized pollution, Carbon, and energy footprints of the energy production, distribution, and delivery systems.

An often overlooked dimension of heating with wood is that the practice of operating a wood heater has the additional benefit of connecting us back to the cycles of nature and to the primal element of fire. Simply setting a thermostat and forgetting about it has the side-effect of isolating us from the cycle and seasons of the Earth.

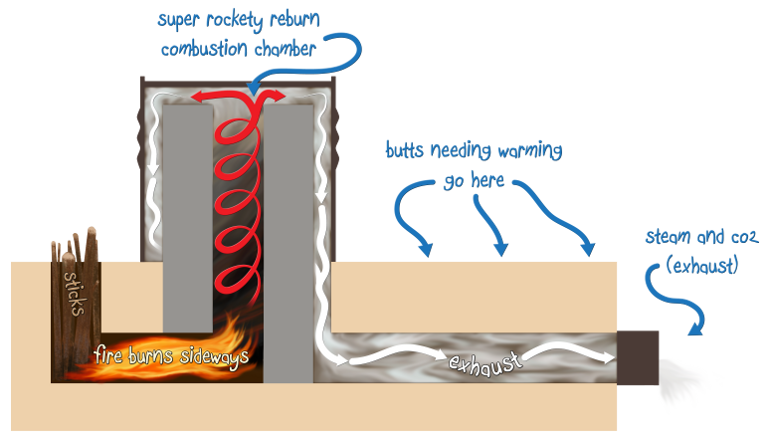

Carbon Negative Mass Heater System Flow Diagram:

For more detail, case studies, and comparisons to alternatives, see Alan's whole webinar here:

https://permies.com/wiki/204703/Carbon-Negative-Mass-Heaters