Uploaded with

ImageShack.us

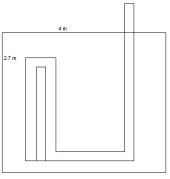

Let me illustrate. When designing your Rocket Stove each section should be considered separately.

Section 1. is the Fuel Source, in our case, wood.

Section 2. is where the fuel and air is mixed. This is where the size does not have to equal the heat riser. According to the Bernoulli Principle, as the pressure decreases(smaller opening), the speed of the fluid, in our case air, increases. Thus increasing "rocketiness". I used equations to prove this as well as tested it. The greater the temperature is in this section the greater the rocket effect.

Section 3. is the Heat Riser where we are taking advantage of the heat expansion of air. This is the work-horse of the stove. This is where the size should be as large as you can make it. This variable strongly effects the rocket effect.

Section 4. not shown would be the barrel which is radiating heat into the room and cooling the air.

Section 5. would be the Heat Bench where we extract even more heat and store it like a capacitor stores electricity for release.

Section 6. would be the exhaust where it finally leaves the building. This section of pipe also can be any size and will not have an effect on the intake. This is because air is compressible. If you have a 4" exhaust versus an 8" exhaust, the main variable effected is the pressure at that point in the flow.

Breaking the stove down into its individual sections and tackling each separately will help you to maximize the rocket effect while maximizing the dollars in your wallet.

I hope this helps.