Phil Stevens wrote:

Peter Chauffeur wrote:This is not your typical build of the "mud and straw builds" that are ubiquitous on permies and I have a profound dislike of using thin gauge oil barrels as bells for the builds I see on this site.

I'm a big fan of horses for courses...deploying technology that is appropriate to the situation. In my case, I have a glasshouse I need to heat over the winter, but not every night. We only have freezing overnight temps about 20-25 times on average. So I built a 4" J-tube, "by the book" with cast burn tunnel, fireclay+perlite riser, a 30-gallon drum as the radiator (NOT a bell because there is no mass), and a cob bench with the flue piped through it. Materials costs were about $100 for castable refractory mix, fireclay and perlite. The drum was free from the local scrap metal dealer. The cob was free for the digging. I spent about a week or two building it, total labour around 12 hours.

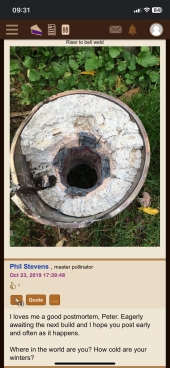

It's been in service for 8 years now and I cut out the warped thin steel from the top of the drum and replaced it with a round piece of 5mm plate. Best griddle ever. I've rebuilt the burn tunnel with firebrick (the cast one disintegrated after three years) and replaced the heavy clay riser with a 5-minute one. So there was an additional material cost, maybe another hundred bucks, and about 3-4 hours to dismantle and rebuild the core. The drum is fine and gets a coating of linseed oil at the end of each season. It does exactly what it needs to do, which is to shed some of the extreme heat after the exhaust leaves the combustion zone, and enhance the system draft via the densification of the cooling and sinking gases. Temps on the cooking surface (did I mention what an awesome griddle this is?) approach 300 C. Readings on the side of the drum usually go from 180 down to 120 from top to bottom. This is not a bell. The thin metal is performing a function quite different from a mass of stone or brick.

The heat storage happens in the cob bench, which warms up to around 35-40 C during a burn and is a really nice place to sit on a cold, rainy night. Someday I might tear it down and replace it with a stratification chamber using barrels cut in half lengthwise, because cleaning out the pipe is not fun and there is a bit of ash in there that is hard to reach from the cleanout ports. But the basic design is performing brilliantly, and the humble RMH should give many more years of service with minor maintenance.