Hi Gabriel

That sounds like a great project, and I hope this reply isn't coming too late. I've built something very similar to what you're describing - a 9m diameter timber frame roundhouse (using roundwood framing), with a reciprocal frame roof, central "eye" skylight, walls of straw bale, cob and cordwood, rubble trench foundation with rock stem wall, living roof, earth plaster interior, earth/lime plaster exterior, etc.

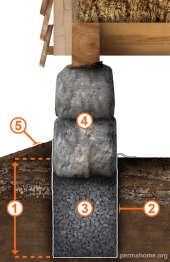

I'm really happy with how it's turned out, and I'm starting to upload some explanatory/instructional videos to YouTube (links to a couple of them below). The only thing is, I'm based in Northern NZ, so we have a very different climate - no frost, no snow loading, etc - so I can't give much advice on insulation and thermal bridging etc. What I would say is that the thermal mass of the place (0.5m think walls, slate tile floor, etc) helps maintain a very steady temperature year-round. We've got reclaimed single-glazed windows (which are draughty) and no roof insulation, but a decent sized wood stove for winter. However, the roof does a really good job of insulating from heat and cold in our climate. The living roof consists of: 25mm sarking boards, layer of tarps to stop dust falling through the boards, foam carpet underlay for padding and some insulation, flexible polyprop pond liner, approx 100mm of punice/soil in a 70/30 ratio, sedum planting which is typically 2-300mm tall and quite dense now. As a reference, we also have a 40m2 timber cabin, which is double glazed with an insulated roof and 70mm thick timber walls, and the roundhouse is always a more comfortable temperature, despite the single glazing.

I've used cob on the sun-facing walls, so it absorbs the heat, and then straw bales and cordwood on the shady walls for insulation.

For the floor, I layered: waterproof membrane, approx 200mm or pumice for insulation, approx 150mm of compacted road base, sand to level, mortar bed, then slate tiles. I laid underfloor heating pipes in the sand layer in case we needed it, but we've been through two winters and it seems fine - as I say, it's a very temperate climate here. Our main issue is the amount of rain we get, especially over winter, and the high winds and driving rain. But overall the building has performed very well. The central aperture of the roof relies ultimately on a bead of silicone to seal, which is not ideal and has led to a couple of minor leaks and repairs (i.e. re-siliconing). I have a couple of ideas on how I might go about fixing it properly, but it's all a bit experimental as I struggled to find good information or solutions on how to do the roof light without spending a lot of money on custom made stuff.

Hope that helps - I hope to be uploading more videos to the channel soon!

Cheers

Jon