Kia Tikaboo wrote:I am currently building a rocket mass stove to heat the perimeter of my greenhouse.

I am using 6" single wall stove pipe to channel the exhaust, and was wondering what the maximum length should be.

I consulted Ianto's book and he indicates a range of 32 to 40 ft.

My run will be 40 ft with 4 90 degree turns.

Does that seem reasonable?

Thanks,

kt

James McFall wrote:I am thinking of building a rocket mass heater and was wondering if the 55 gallon drum has to be food grade or not.

Thank you.

canyon

canyon

Andrew Parker wrote:Jason,

The internal heat riser in the RMH is not what makes it a rocket stove.

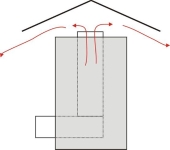

A rocket stove is, IIRC, an insulated (though not always insulated) duct or flue of relatively constant internal cross-sectional area, in the shape of an L or J (though not restricted to those shapes). The constant cross-sectional area keeps the gases moving. The insulation helps to keep the flue gases from cooling before combustion is complete and maintains draft. (Those are the rockety parts)

In an RMH, the internal heat riser, made by putting a barrel over a J-shaped rocket stove, is used to help passively pump hot flue gas through the labyrinth of ductwork.

Jason Munzke wrote:I have the same type question. Is there more about converting woodstoves into Rocket Heaters. I want the efficiency (or near the efficiency) of the RMH with the quick radiation heat of my cast iron stove, to be used as a sauna.

Canyon

Canyon

Canyon

Canyon