Efficient in terms of what output, for what input? Do you want it to be easy labor, best drying, most wood in the smallest space, easiest to build? What's the priority?

Don't stack wood without some kind of roof. Wood will not shed rain well enough on it's own to get really dry. It can be an open sided shed, or something more enclosed but with good ventilation. The more loosely it's stacked, the better the air flow and the better the drying. Some solar gain helps.

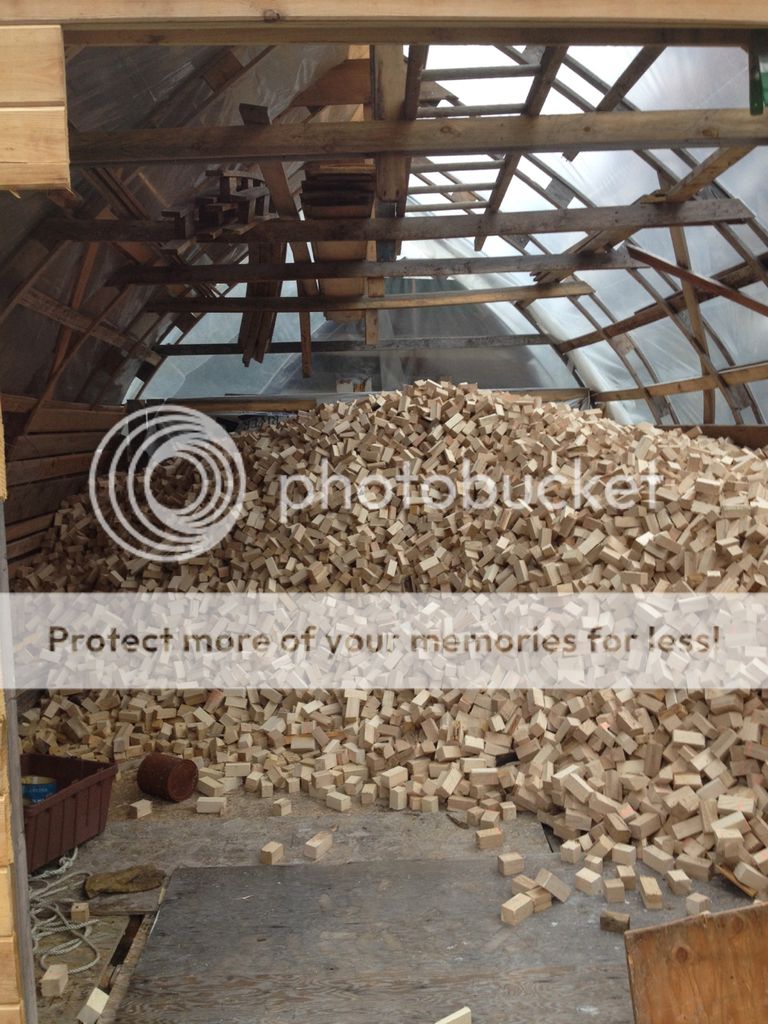

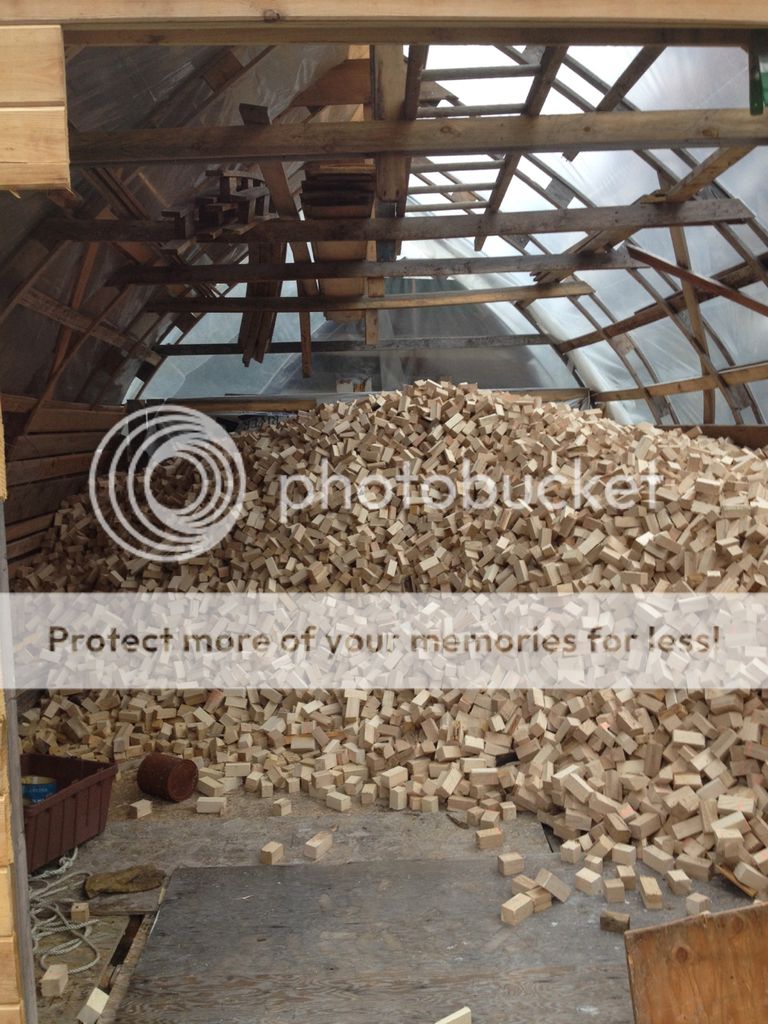

My primary fire wood is small manufacturing waste hardwood blocks. I shovel them into my truck at the factory, shovel them into my drying shed (above), shovel them into totes to sled over to the house.... There's not much bending. The drying shed has a slat wall behind the pile of blocks. I sometimes open the double doors on the near end for ventilation on sunny days, but I close it up in storms. I hate snow-covered wet firewood. The north side (left) is boarded and roofed, more or less, but the south side is greenhouse plastic above the fist four feet. The first four feet on the south have slats to hold back the wood, and air can come up from below. The whole thing is on pallets, over two layers of plastic lumber wrap on the ground. That way I get air flow from below without soil moisture. On top of the pallets I have plywood scrap, which slows air flow (bad) but makes shoveling much easier (good). There are still some air gaps around the pallets.

If I'm dealing with logs, I use a picaroon, like this one (not my picture). If you wanted one cheap, they were traditionally made by grinding a hook point onto an old axe head, but you might also make one by cutting off one claw from a big framing hammer, and sharpening the other one to a point. They greatly reduce bending and lifting. Mine has a handle the length of my old furnace firebox, so that as I work, I know if the log will really fit. These work much better than hay hooks, IMHO.

Some feel that stacking in long rows in the weather for a few years is good, but then the wood should be moved under cover for the final drying. This just sounds like extra work to me.

Wood should not be dried in the living space. That's too much moisture to put into the structure of your house without encouraging mold and rot. The only way this isn't true is if you have a house that's unlivable because there are so many air leaks.

For stacking in the stove, efficient means efficient combustion. it's mostly an issue just when starting the fire, but make sure there's a good vertical air channel through the fuel, but the flame is able to heat the rest of the fuel. Like I said elsewhere, putting two dry split faces close to each other with a vertical air channel between them makes for better fire starting. Lots of wood stacked in horizontally, with the vertical paths clogged with the ash of too much paper tinder, will not catch easily.