Mart Hale wrote:

Yes, other things to look out for is don't use wet sand, it gives poor results and steam can be a real issue with the heat source you are using.

I have been thinking that the cob rocket mass design, or mason heaters might be a good place to look for design ideas as they already store and release heat for home heating....

Oil gives great advantage as you can almost go heat on demand....

Attached is a photo of a guy who uses waste heat for his outdoor spa... It has "BOOM SQUISH" written all over it, but the concept looks good just needs regulation of the heat ;-)

Mart Hale wrote:I have a long thread on the sand battery (snip snip)

This is a proven method of using waste oil, it deals with all the problems of impurities in the oil.

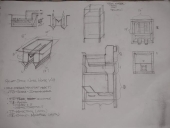

Glenn Herbert wrote:One important factor that I have not seen mentioned is that you are putting a heat exchanger around the burn tunnel/heat riser area.

Anne Miller wrote:Something that might be a consideration is using the water as a mass and running it under the floor.

I have only read about this concept though I like it.