Jonathan of The Tiny Shiny Home YouTube channel posted a video called

Composting Toilets are a WASTE of TIME this week. I watched it and it made me a little angry. The straw man arguments he made I found really infuriating. I'll put a link to the video at the end of the post and summarize the arguments in my rebuttal.

Background: Jonathan has a family of six. They started using a Nature's Head Composting Toilet in 2017 while living in an airstream trailer. In 2020 they moved the trailer onto raw land in Arizona where they continued to use the Nature Heads while building a hyperadobe home. Jonathan built a composting toilet system on the property composed of 5 or 6 50 gallons barrels with urine diversion. I think the idea was that once a barrel became full you covered it and moved on to the next barrel. He said in the video that that experiment was a failure.

Argument #1/Hot Take: Composting Toilets are huge time sink

In the video there's a montage of Jonathan cleaning the Nature's Head Toilet and emptying the urine collection. I think the lesson here is to size your system appropriately. With just one collection vessel using a Nature's Head for a family of six is going to be a lot of work. You will be emptying and cleaning the collector at least every other day. I know a family of five who uses a Joseph Jenkins humanure system with five gallons buckets. They change out buckets every other day but they have a lot of buckets so they do a bulk empty and clean once a month.

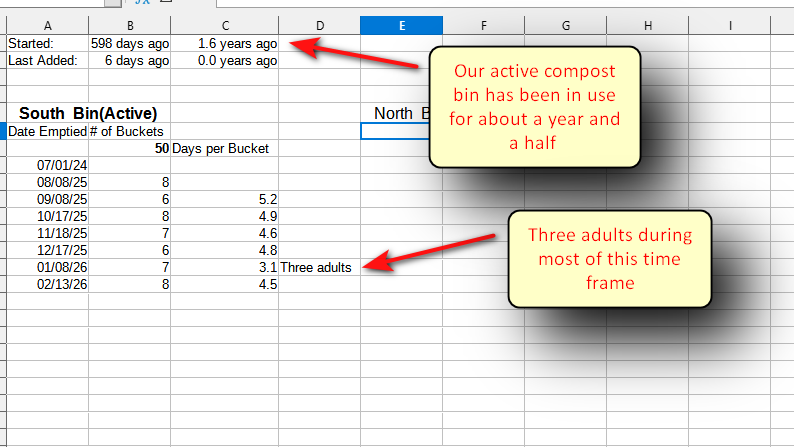

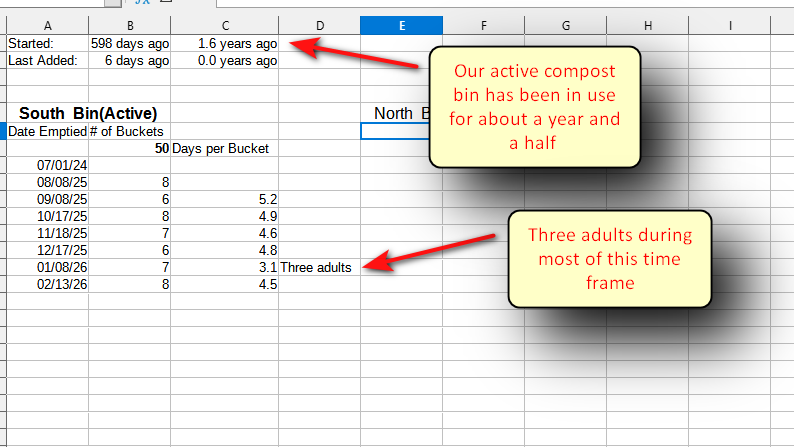

We use a similar system at our house. With two adults it takes 4-5 days to fill a five gallon bucket. When a bucket is full I put a lid on it, put it in our bucket holding area, wipe down the toilet seat and drop in a new bucket. I have eight buckets in circulation so I empty the buckets into our compost bin and clean them about once a month. The process takes about half an hour. I haven't cleaned a flush toilet in a while I think the time commitment is comparable.

The willow feeder system is even more time efficient because it uses larger collection vessels and skips the step where you empty the bucket into a compost bin.

Argument #2: Composting Toilets are a long term commitment

I agree with him on this point. When constructing a house it is a good idea to think long and hard about how to future proof it. In our case, I installed a toilet flange and plumbing necessary to install a flush toilet if necessary. We have a septic system sized for a flushing toilet (per county requirements).

Argument #3: Composting Toilets can be problematic with a not fully on board partner/spouse

If you can't tell I'm a bit of a waterless toilet aficionado. My wife is not as enthusiastic about the in and outs of human "waste" management but we have a compost toilet that's fairly low maintenance, looks nice, is comfortable and most importantly doesn't smell. I believe that if you create an elegant system you can win over just about anyone except for probably your county health and human services official. If you're married to your county health and human services official I guess I can give you a pass on this one.

Argument #4: Composting Toilets don't handle diarrhea or vomit well

I disagree. Paraphrasing Uncle Ben here, "With great amount of liquids comes proportional amounts of cover material," and Saint Peter, "Wood chips cover over a multitude of sins." And with projectile vomit you get the added bonus of no toilet water splash back.

Argument #5: Composting toilets are awkward with guests and often end up in disaster

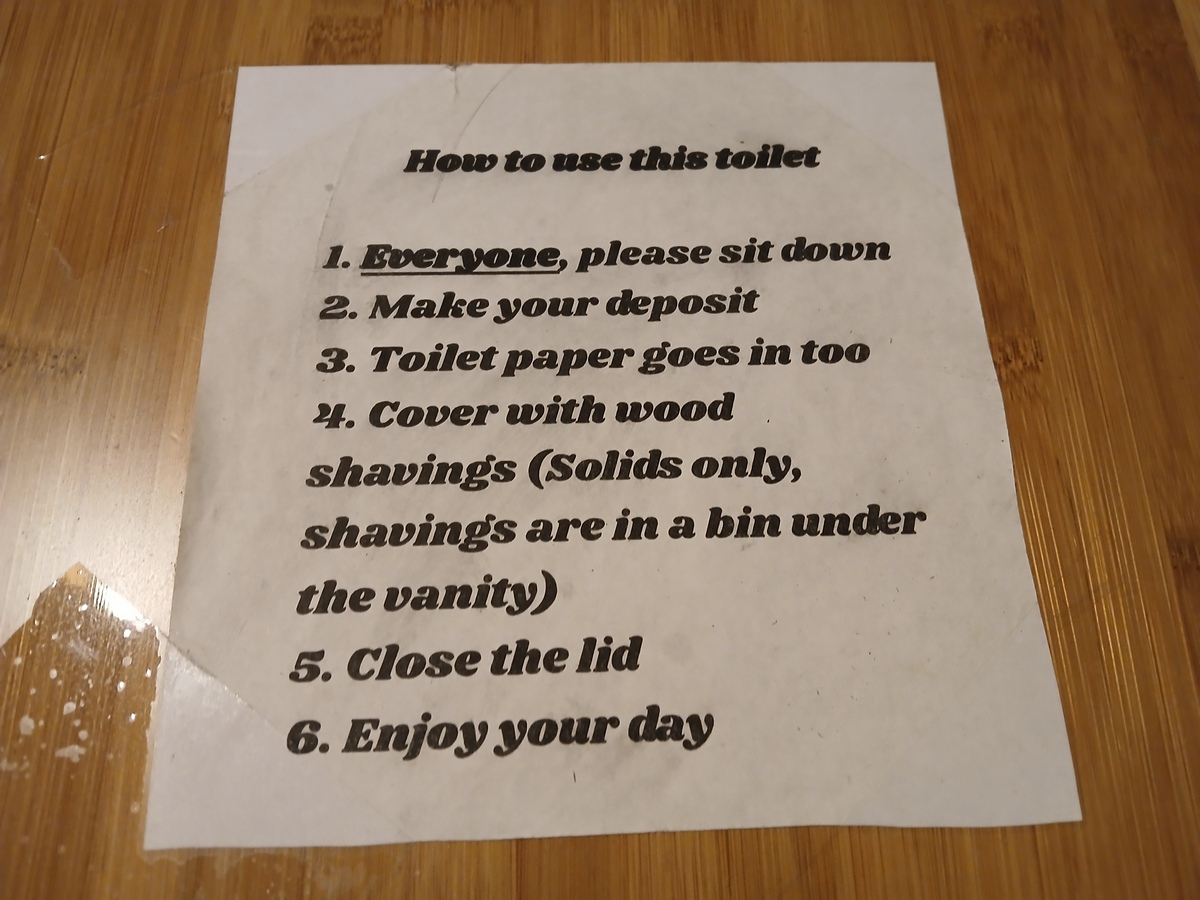

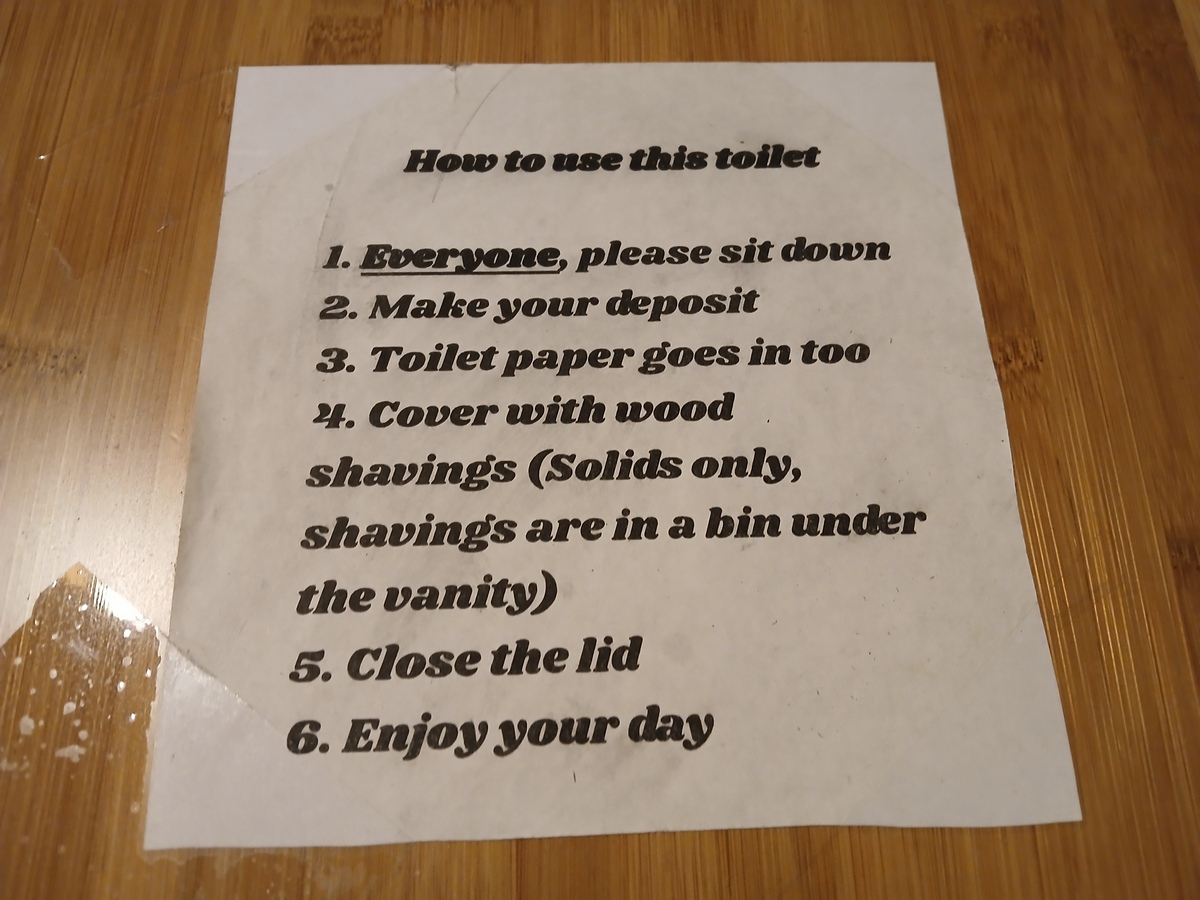

We have a short set of instruction posted on our toilet seats and have never had a disaster much less any issue. Even if someone chooses to defy the sit down to pee rule that little bit of excess moisture has never been a problem.

Argument #6: Composting toilets are ideally suited for one to two individuals and/or infrequent use

Argument #6: Composting toilets are ideally suited for one to two individuals and/or infrequent use

I agree that the Nature's Head Composting Toilet is ideally suited for one or two people. However, you can size a waterless toilet system to fit a wide range of users and usage patterns. The Willow Feeder at basecamp in Wheaton Labs is a good example. It sees some periods of pretty heavy use. We sometimes have long term guests expanding our effective household to 3 or 4 and our five gallon bucket system is flexible enough to handle it.

That's the end of arguments against composting toilets. I think it is a pretty weak foundation to make sweeping generalizations from. What really bothers me is that loads of people will watch that video and not think about it very critically because it confirms their bias. Thanks for the rant space. Here is that video if you're so inclined: