Well hello all…

I’m having some difficulties with a RMH I’ve built for an aquaponics green house I’m constructing. I’ve got so many figures in my head and I want to only bother you fine folks with the facts you need to properly analyze my situation. Of course I’ll be happy to answer any questions you may have about my use and build as they are posted.

I purchased the book by Evans & Jackson a couple years ago and have largely tried to base my construction on the “science” in that book. I have obviously strayed from the main design in that book as I have some rather special features I’m needing to incorporate. It would appear however I’m missing or have yet to incorporate some important aspects of the RMH in my design.

I intend to use this RMH to heat water in an aquaponics greenhouse. The exhaust is buried under a 1500 gallon sump using an 8” pipe. The water will not only heat the fish tank it's pumped to but eventually all the grow media rocks used in the four 4’ x 20’ grow beds. I’m sure it will take a considerable amount of time to stabilize all this mass. But I’m hoping it will also hold onto that temperature once it has captured it.

I’ll post some pictures and try to briefly explain…

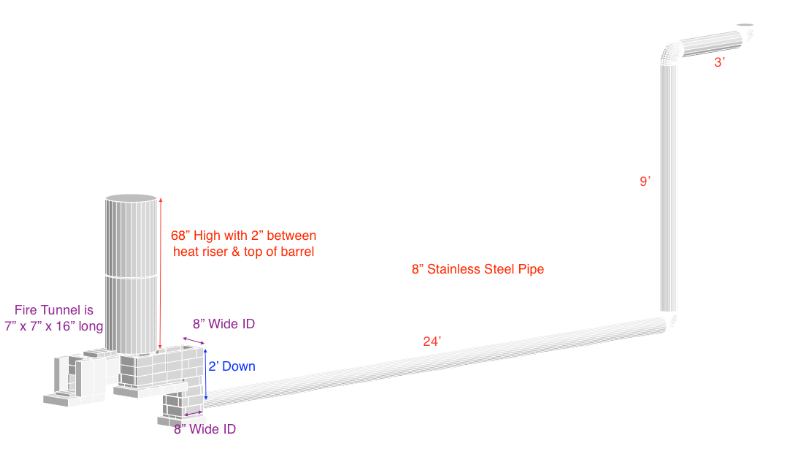

Above is a CAD of my basic design. The exhaust or horizontal flue sets 2’ under water. It runs under a 24’ long body of water before rising 9’ feet and then through the wall. At the moment the flue stops there just outside the wall under an overhang outside. I have played with the idea of placing a fan out there to help the draw. The heat riser is made of an 8” steel pipe 1/4” thick. It is insulated with the vermiculite/clay mixture described in the book. The insulation is 3.75” around the heat riser. There is at least a 2” space between the heat riser and the top of the capping barrel, there may be more. The heat riser is also completely offset in the barrel to reflect the heat toward the inside of the greenhouse. It also directs the flow strait down into the ash pit area. It then moves over to where it will go down 2’ below the water.

When the heater is running well the pipe at the other end is cool enough to put your hand on. It’s only barely warm with the smoke wafting out lazily.

Above is a view of the system as it is now. In the distance the 9’ pipe up the wall can be seen. Coming forward is the 24’ sump of water. In the foreground is were the main RMH can be seen. The ash pit and 8” x 9”

(the 8” Wide ID label at the bottom of the CAD picture should read 9”) square channel where the exhaust goes down under the water is covered with a 1/4” steel plate.

The above picture is a view with the 1/4” steel plate removed for clarity. The narrower fire bricks seen in the middle was where I planned to introduce another exhaust pipe should I need to redirect heat if the water in the sump was getting to hot. At this point I don’t see it being needed.

Above is a closer view of the current fire tunnel and feed area of the system. This is obviously were I’ve been experimenting and playing with different ideas. Generally the stove is easy to start with little or no smoke. I usually start a fire just inside the fire tunnel. As it is getting started I’ll blow a little to encourage the heat up the riser and that’s usually enough to get things started. The lower area is a clean out area. My thought was to use a stainless steel grid or grate that spans from the end of the fire tunnel over this ash clean-out area. As wood burned it would fall through the grate and could be easily cleaned out there.

The Main Issue…

I think the main problem I’m having is not enough draw to start with. If there is much breeze or wind outside, the draft is easily overcome and smoke begins filling the greenhouse. As is visible I’ve played with different feed tube designs but inevitably have had to cap them off to keep the smoke and eventually fire from coming out the feed tube. I’ve actually been using the capped feed tube as a place to hold sticks of wood that gravity feed down into the ash pit area where they burn there. Oxygen is supplied down at the door of the ash pit. I’m aware that I need to better seal and insulate this fire tunnel area but was wanting helpful input as to move me in the write direction or even point out some concerns elsewhere before I proceeded. I may even have to rebuild something (perish the thought).

Also at times when the stove is running well, I need to feed it about every 45 minutes if I’m to keep the rocket going. Any ideas on getting a halfway decent nights sleep in the wintertime? I have had some thoughts myself but am interested in yours out there. I was thinking the feed tunnel could be lengthened to allow longer sticks of wood to be used as fuel. That will not work however if the fire is just going to work it’s way right up the feed tube.

There is much more information I could give but think I’ll wait for questions and answer those.

Thanks again for all your insight!