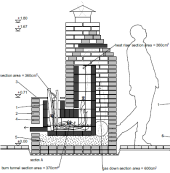

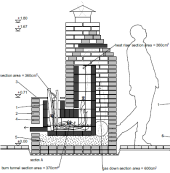

Hello again! So, I had a chat with a local oven-builder. He doesn't have experience with Rocket Mass Heater, but with typical german mass heaters. He thinks that we will have problems starting the hot gases circulating in the system, because it is very cold outdoors in the german winter and we will not have any difference in temperature between the feed tube and the chimney. Normally, if it was built for indoors, we would have a difference in temperature because the feed tube would be indoors and the chimney would be outdoors. So, he believes that a) it would be very difficult to start directing the hot gases in the way they have to go, and that it would smoke from the feed tube. So, he suggested to make an by integrating a stove-door in front of the feed tube, and a removable schamotte-slab to close, when the front toor is open, the feed tube from the top. In this way, we could start the fire from there, by feeding the wood horizontally, and once the system is hot, to close that door, and continue feeding the fire from the top. He also said, that it would take 5-6 hours until the bench gets warm, because the bricks will be really cold if it's very cold outside.. I would be interested to know your thoughts on this matter. FYI, we will make the heat riser two bricks higher and the bell will also rise accordingly.

Also, how do you clean the ashes from the feed tube? We need a system that it will be easy for the people in the neighbourhood to understand how they can use it and maintain it.