3D Plans - Pebble Style Rocket Mass Heater

will be released to subscribers in:

soon!

Cristobal Cristo wrote:Fraser,

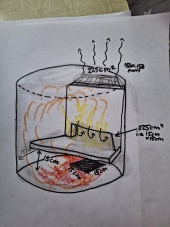

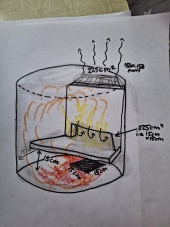

Double core will be very impractical. I would try building a 25 cm batch box with shortened riser.

Is your core hot to the touch on the outside when reaching 640 C in the kiln?

Glenn Herbert wrote:No matter the size of your firebox, a pottery kiln will need to be fired without interruption from start to finish. Not just back to back firings, but reloading before the fire burns all the way down so heat input never falters.

You also need to be able to start the first fire slowly so the kiln temperature does not rise too fast and explode the pots. That is a matter for control rather than capacity, though the larger the firebox compared to the kiln the trickier it is to meter it. In my wood fired, cob-built kiln, I start the fire in front of the firebox and gradually over the course of an hour or so move it inside for gentle temperature rise. The firebox is about 4' long and 16" high and wide.

Cristobal Cristo wrote:That's much better result, but still too low. You could try wrapping the core on the sides and the bottom with some insulating material, but I think it will not be enough. You already have IFB bricks so you could try to build a 25 cm batchbox and see what happens. If the temperature rises to much more than 640 C then you will know which route to take.

Phil Stevens wrote:Wrapping the core in CFB will help - not as much as using insulating firebrick but at least once the core gets up to operating temperature it won't be shedding so much heat. That would be a lower cost interim solution and might even do the trick.

Fox James wrote:I think you would stand more chance with a 10” batchbox and a step ladder.

Vermiculite board might be available to you as it is widely available in Europe, it would certainly last long enough to do some testing but might not last long term.

I am all up for experimenting and I really hope you find some success but I think there are better ways.