Buy Our Book! Food Web: Concept - Raising Food the Right Way. Learn make more food with less inputs

Off Grid Homesteading - latest updates and projects from our off grid homestead

Buy Our Book! Food Web: Concept - Raising Food the Right Way. Learn make more food with less inputs

Off Grid Homesteading - latest updates and projects from our off grid homestead

Abe Connally wrote:so you have this running? could you show us some photos of the unit and a build sequence?

what sort of pressures are we looking at? would PVC/galvanized pipe work?

how much heat must be applied to keep the process running?

![Filename: CO2-Critical.png

Description: [Thumbnail for CO2-Critical.png]](/t/28388/a/12067/CO2-Critical.png)

![Filename: Carbon_dioxide_pressure-temperature_phase_diagram_svg.png

Description: [Thumbnail for Carbon_dioxide_pressure-temperature_phase_diagram_svg.png]](/t/28388/a/12069/Carbon_dioxide_pressure-temperature_phase_diagram_svg.png)

Creighton Samuiels wrote:What do you expect to happen once the dry ice is gone?

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

allen lumley wrote:et al : think of it as a pump that works off of the heat energy, its a very simplistic answer But, when, not if, this can be made from parts made on a 3-d printer -

(rocket exhaust nozzles by collage students any one?! ) This too is doable !Big AL !

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Peter Mckinlay wrote:

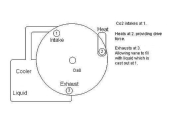

Pressures are 1 bar at -40*C. 10,000 bar +100*C.

Peter Mckinlay wrote:One litre of heat per second is required.

Buy Our Book! Food Web: Concept - Raising Food the Right Way. Learn make more food with less inputs

Off Grid Homesteading - latest updates and projects from our off grid homestead

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Abe Connally wrote:

Peter Mckinlay wrote:

Hello Abe,

Pressures are 1 bar at -40*C. 10,000 bar +100*C.

10K bar?!?!?! holy cow!

&20 watts for each litre of gas/water per second at 9 bar pressure.

I don't know much pipe that will handle that kind of pressure.

Stainless steel is lighter than using line pipe for high pressures.

Peter Mckinlay wrote:One litre of heat per second is required.

I don't understand this figure. What is a litre of heat?

A litre of heat is the heat need to raise the heat of one litre of liquid to a required heating.

Ok, let's talk about a practical build for a small off-grid home. I have a hot water storage tank that stays around 50C year round. It holds 1200 l of water. It's heated with solar panels in the day.

I would like to use heat from that tank to produce, say, 50 watts of electricity constantly.

Our work is generally with KW and MW, however a Pelton micro will suffice your needs.

How big of a system would I need to build to do that? What pipe sizes and turbine options are available for a build like that?

Flow rate and pressure for 50 amps you would need refer to micro Pelton. Without that is pure guess to size of piping etc. is needed. Micro Pelton are fully web available.

I assume I need a cold side as well. I have several cisterns of water, 40,000 l in size, typically around 15C year round. Would that be enough of a temperature difference to power this system?

![Filename: CO2-Critical.png

Description: [Thumbnail for CO2-Critical.png]](/t/28388/a/12075/CO2-Critical.png)

allen lumley wrote:Peter McKinlay :Have you taken a close look at the way the Pelton Cups are shaped and mounted to receive the spray from the nozzle?

TheWater first hits a sharks tooth point, splitting the water stream into two streams that hit siamese 'd 1/2 cups and rebounding back off, increasing contact time,

and the 'for every action there is an equal and opposite reaction' event within a very narrow window of incidence !

sorry about my word choice, tell me a better way to say it

This leaves us with well drained cups, and like the way a single piston in a 'V-8 engine is carried along until its next power stroke, the 20-ish cups work as a team

( with much less friction than our V-8 image ) what would the temperatures there be !

Again, This seems a perfect match to developing 3D Tech.!

Go to - ' pioneer-sys.net/microhydro.htm ' - the sketch at the bottom of the page is better than several videos i have seen !

Central pipe Reducer ? = Bell reducer= two sets of female threaded openings? and that was not a misprint on the# of BARs ? For the craft ! Big AL !

1

1

Buy Our Book! Food Web: Concept - Raising Food the Right Way. Learn make more food with less inputs

Off Grid Homesteading - latest updates and projects from our off grid homestead

|

Well THAT's new! Comfort me, reliable tiny ad:

GAMCOD 2025: 200 square feet; Zero degrees F or colder; calories cheap and easy

https://permies.com/wiki/270034/GAMCOD-square-feet-degrees-colder

|