1

1

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Mike Cantrell wrote:From what I gather, the "normal" 6" batch box is finicky- it has to be just so in order to run well. The 4" batch box is much more finicky, and very challenging to get to run at all.

It it were me, I'd build a 6" batch box and figure out how to shed the excess heat, rather than taking my chances on something that might take a few rebuilds to get working.

1

1

1

1

regards, Peter

1

1

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

4

4

regards, Peter

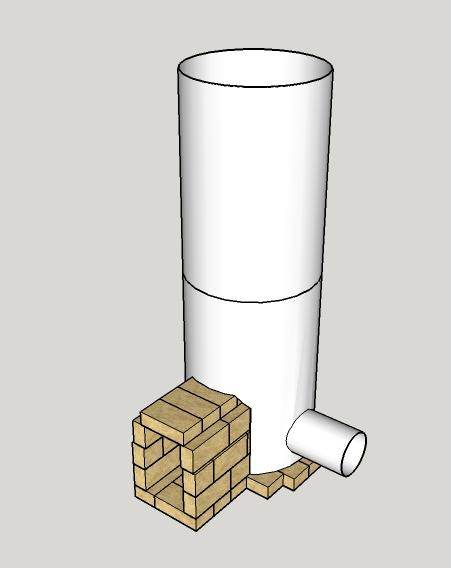

Rick Edwards wrote:After the second barrel, can the exhaust go up to 8" if we have more of that laying around?

Peter. Thanks for the plans, most excellent.

regards, Peter

Chimneys can be larger diameters as the heater, not smaller.

Jay C. White Cloud wrote:A chimney within a wood burn system for a given combustion shaber for a given run of horizontal, and Up down radiant passages should fall within certain parameters depending on multiple factors of location, elevation location of build, and general design of system...These chimneys are meant to match the system...definitely not undersized, yet too large will also cause inefficiencies, and/or failures.

regards, Peter

best regards, Byron

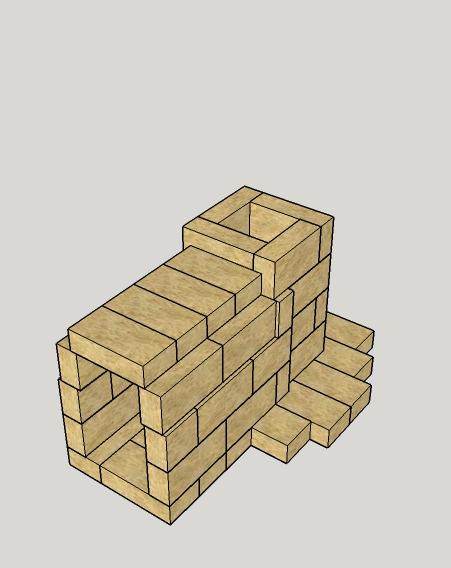

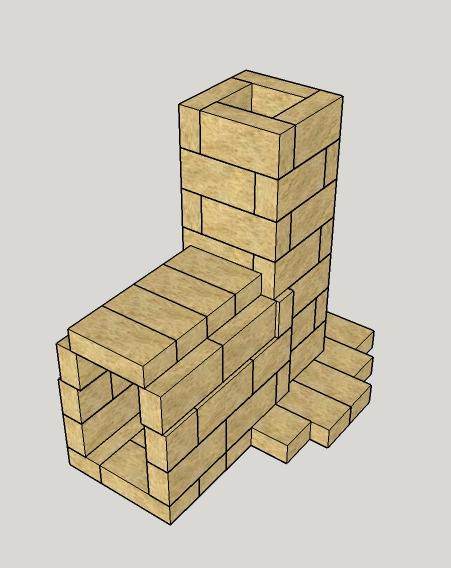

Byron Campbell wrote:Thanks also for the brick layout Peter. I have also been thinking about building a brick 6" batch burner, but thinking about substituting for the steel barrel(s) a small brick/masonry bell and brick/masonry bench of some sort. Nothing fancy of course, just a small cabin heater of sorts. Has this been done before?

regards, Peter

regards, Peter

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

2

2

1

1

Rick Edwards wrote:We are moving forward with Peter's plan and I'm considering a P-channel as well so it can have more push hopefully.

Rick Edwards wrote:1. could you remind me the csa of the primary air intake? I'm thinking 20% system size.

Rick Edwards wrote:2. also using these dimensions I'm going to start cutting brick to size Could you double check for me please.

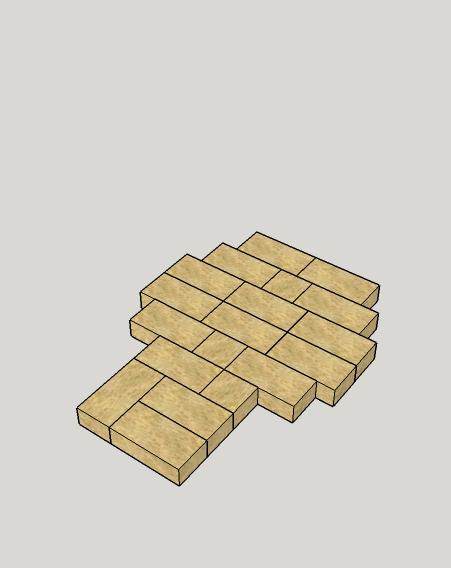

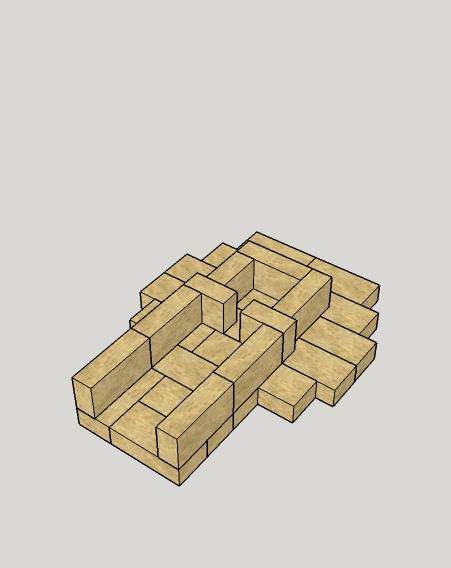

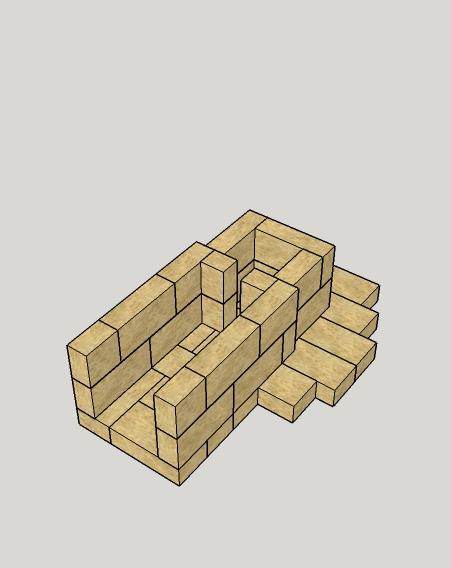

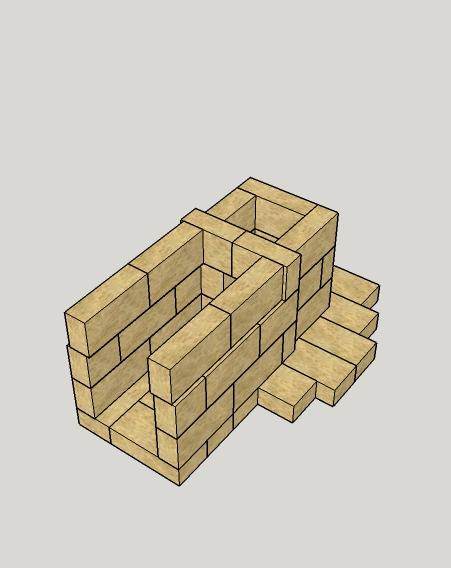

System 6" diameter or 5.3" square riser.

riser height 43 3/16"

box width 8.64"

box height 12.96"

box depth 17.28"

port width 2.16"

port height 9.5"

P-channel W 2 3/16"

P-channel H 5/8"

Primary air intake 20%?

Rick Edwards wrote:3. there will be a door of duraboard like the auditoreum for better draw.

Rick Edwards wrote:4. Was thinking of duraboard top for ease of install.

Rick Edwards wrote:Any problems let me know and thanks for the sloping tips.

also when using a square riser could it be better to rotate the riser 45 degrees to help the rams horn?

regards, Peter

Rick Edwards wrote:

when you say clay to sand 1:1 do mean dry clay to sand or clay slip to sand?

Rick Edwards wrote:and what are you referring to as the kaolin clay, our local clay or one of the purchased clays we have around the shop.

Rick Edwards wrote:Also i was going to wrap the riser areas with durablanket for insulation and better push.

regards, Peter

Rick Edwards wrote:P-channel should be 1.41"sq.

Is it better slightly bigger or slightly smaller.

I can get easy 1.3125"sq or 1.53"sq

regards, Peter

Rick Edwards wrote:Riser can be 40 or 42.5 or 44.5.

Any thoughts?

regards, Peter

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

|

I will suppress my every urge. But not this shameless plug:

Learn Permaculture through a little hard work

https://wheaton-labs.com/bootcamp

|