Glenn Herbert wrote:I think you have been misled by a lot of youtube videos, which are not made by people who build rocket mass heaters regularly, but by experimenters who are familiar with woodstoves and maybe rocket cooking stoves.

I'll start with this because you are 100% correct. I've also read about 30 build threads in this category so I'm meshing the information together. As you can understand, it's easier to comprehend the information presented in a visual vs text format.

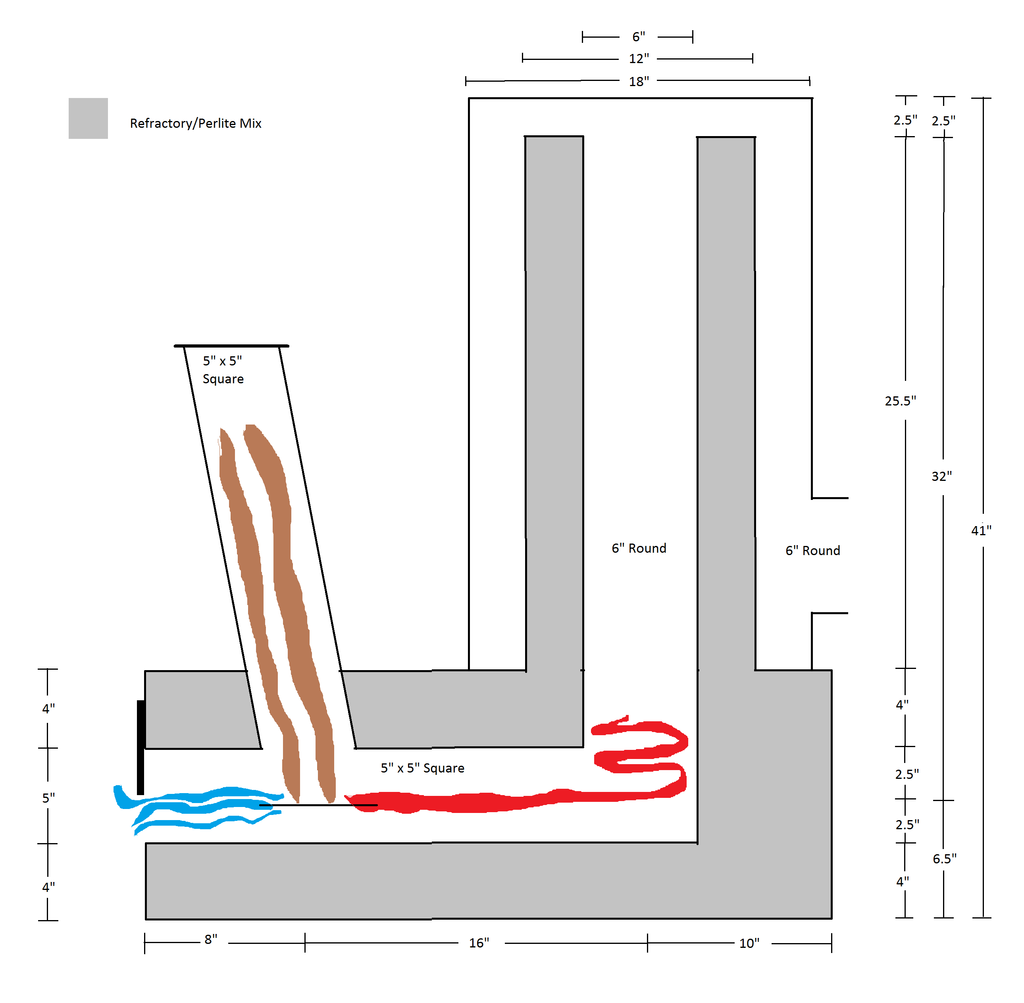

Glenn Herbert wrote:I'm sorry, but you seem to have misunderstood the way a RMH core with the 1:2:4 proportions is supposed to work. The 8" dimension is the vertical wood feed AND air intake; the 16" and 32" dimensions are correct. There is no front air intake. Also, the feed works better completely vertical than slanted.

Okay. I thought by separating the air intake from feed tube it would give me control over the amount of air to fine tune the burn. Are you saying that controlling the amount of air entering the heater isn't important?

Glenn Herbert wrote:

If you think that a front access port is needed for ash cleanout, I can assure you that it is not (unless maybe you have gorilla-sized arms). I have cleaned a 6" x 6" J-tube with my bare hand, and with a sardine can on a short handle, easily.

It was primarly to be able to control the amount of incoming air.

Glenn Herbert wrote:A 5" x 5" core would be trickier, but for a 6" duct size system, a 6" x 6" core would be fine.

I planned for a 5" x 5" core based on the information I found on this site in reference to matching the area of the 3 components of the J tube design. 5" x 5" square tube has an area of 25". A 6" round tube has an area of 28.27". Where as a 6" x 6" core has an area of 36". It's possible I'm also confused about that concept as well.

Glenn Herbert wrote:Can you give us any information about your plans for the system? What kind of mass, how long, what size of space and how insulated, how you use the space, what your climate is like?

I don't plan on heating a mass with this design. So it

should be considered a rocket heater. I apologize if there is a rocket heater category on this forum and I missed it.

I plan on using the rocket heater in my 1400' garage. The walls have fiberglass insulation rated @ R13 and the ceiling has 8" of blown cellulose rated ~R24. I like to spend my evenings tinkering on vehicles or building projects. I live in North East WI where the heating season is relatively short and there are very few days where the temperature falls below 0 degrees Fahrenheit.

I don't need the entire garage heated to 70*. I plan on positioning the rocket heater in a location where the radiant heat from the drum will be near the area I work in. It would

be nice to fire up the heater 30 minutes before I plan on working in the garage and run it for up to 4 hours a night.

I plan on using a 30 gallon steel barrel as my bell but they are hard to find in my area. The

local scrap

yard sells 55 gallon drums for $10 but crushes 30 gallon ones for some reason. Brand new they are $45. I'm hoping that the thin gauge of the steel barrel will be great for radiating heat into the space.

Glenn Herbert wrote:It may be helpful to explain that having the wood feed capped off and air coming from the front will let the wood get hot and char up into the feed tube. When you open the cap to add more wood, you risk a puff of smoke or even flame bursting out of the top and singeing your eyebrows off. The air intake pulling down from the top keeps all the fire and smoke moving in the right direction, and you can clearly see when you need to add more wood.

I never considered that. I was more concerned with having control over the amount of air entering the burn chamber. As I have observed on Youtube, the burn can be dampened to optimize wood use and output temperature. I've also observed the "capping" of the feed tube and use of a front air intake on several RMH/RH that were converted to run pellets. I have no plans on running pellets in my heater.

Glenn Herbert wrote:The 16" burn tunnel dimension is a maximum, and if your barrel clearances allow, you can make it shorter and get better draft.

That is great to know. I can make it shorter and would prefer a shorter design to safe space. I've seen other builds on this forum at 1:1.5:4 or 1:1.3:3.75 ratios. I tried to find a

thread on the general concept of the ratio minus the specific detail of build but fell short.

So "In General"

If the equation is 1:X:Y

X can be <= 2 but has to be > ?

Y should always be as close to 4 as possible?

Glenn Herbert wrote:Keep the feed vertical, though. The best method I have found (also recommended by everybody I have read) is to lean the sticks away from you so that they lean against the burn tunnel roof, and air has to go down on your side of them or through and between them to get to the fire. This keeps the tops of the sticks a bit cooler and helps preheat the air. If you lean the sticks back toward yourself, the air can flow down on the far side of them and leave some of them starved for air, while a lot of air goes into the burn tunnel without meeting the burning coals.

I understand what you are saying. I think I have seen an image on this forum demonstrating the concept. It's like the sticks are stabbing the fire vs the fire flowing from the sticks.