If you are in a non freezing climate, you can circulate water from the tank to the collector(s) and back to the tank. Cool thing about open (atmosphere) tanks, aside from being able to modify exchangers readily, is being able to adjust tank volume.

My favorite for this are stainless steel wine vessels with adjustable covers for tank volume.

Totally forgot this aspect. Your collector is a twofer-one, where it can be kept from freezing, unless it is seasonal use.

Your collector capacity in btu or watts is handy to know. But it sounds like you have an idea of performance.

Our shower served 5 people with one 4' x 20' pool heating collector and no additional heat exchanger. One pump (shurflo diaphram) circulated the collector circuit to drainback (freeze protection and heat scavenging) and the other pump (small centrifugal) discharged to the shower shed and outdoor sink. All plastic and from freebies and other discards aside from a customized nursery sprayer, cheap faucet and a couple fittings.

The tank is the same tank we now use indoors for a thermal storage battery and wears its original wraps of reflective "double bubble ", the thick stuff.

We manually filled the tank with a valve and used a float and flag and an indoor/outdoor thermometer for instrumentation. A salvaged, 25 year old differential thermostat from a solar air heating overhaul controlled the collector pump.

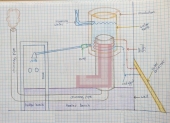

For household use we use ivan labs dc circulators for collector and boiler inputs to storage. The collector circ is pv direct and the boiler circ is battery connected through battery and pv direct capable differential thermostats from Guy Marsden. Great devices.

http://arttecsolar.com/

The boiler circuit drives purified water to the woodstove heat exchanger (<60' coil of 3/8 soft copper, drinking water safe) and back like a fountain into the tank 20' away.

Our collector loop (collector mounted, unfinished plumbing), feeds a 4'x12' glazed reynolds aluminum collector. It will not drainback, much like yours, as its risers are serpentine. This requires antifreeze or fluid evacuation in our climate. A pressurized loop that operates with extreme potential stagnation temps precludes the use of plastic plumbing, though some people do it and certain arrangements are designed to.

If our collector would drain back, we could just omit the collector heat exchanger

Our domestic hot water is pressurized by the well pump and delivered to 250' of 1/2" pex., and somewhat under-performs the way i did it, but it work for the money we have into it. It has served for about four or five years.

It needs longer coils by double or half the flow rate through it with two more coils. This will not fit well. I will calculate for a switch to copper.

Observation of feed and return temps and flow rate (or use, like shower, dog heater, sink, etc.), and time, set up as a test bed or the maths will help determine. There is a point where space limits the practicallity of adding more plastic tube. Plastic is not a great heat exchanger generally.

Your 250 gallon tank has room for plastic, and it sounds like you have enough information to slog through the math. Keep the temps within the limits of your tank and plumbing and the water level at a reasonable level so that it reliably comes up to a usable storage temp.

This brings me to think about your "radiators" they have a thermal and likely an electrical load. They also have a temp range for usability. These want to be known before investment of materials and time.