2

2

1

1

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

1

1

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

1

1

thomas rubino wrote:If the copper plate isn't quite right for your design. Leaving your granite back 1 to 1.5 " back from the edge of the fire brick will certainly help protect it from the heat. Gerry suggested possibly using ceramic fiber board (1/2") under your granite that is over the feed tube. This would work fine as well. I would still keep the granite away from the edge.

I tested the temps on my stove last night. The top of the fire bricks were 225-250 F if I measured down 2" temp was 570 F +

1

1

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

1

1

thomas rubino wrote:

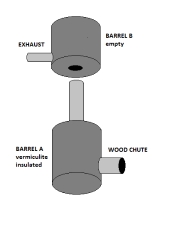

For your application, of a showpiece rmh that folks can sit on . I would consider using the Walker style 1/2 barrel's in your bench. They would heat up your bench faster than a traditional pipe thru mass method.

2

2

1

1

2

2

2

2

3

3

Silence is Golden

For all your RMH needs:

dragontechrmh.com

3

3

Staci Kopcha wrote:Hi Dan!

I have't watch video or read details yet- looking forward to it.

The end product looks Awesome!!

Very "low profile" for a rmh!! Mine seems like a sloppy goliath in contrast. (earnestly working on plaster this weeked!)

Are you please with performance?

Staci

|

This tiny ad cleans with warm water instead of toxic gick and gained 20 IQ points!

A rocket mass heater is the most sustainable way to heat a conventional home

http://woodheat.net

|