Three days of hands-on learning, March 27-29 2017

Cost: $30

Contact: Windward@gorge.net to register.

Pay via paypal, link at this address: http://www.windward.org/springbreak

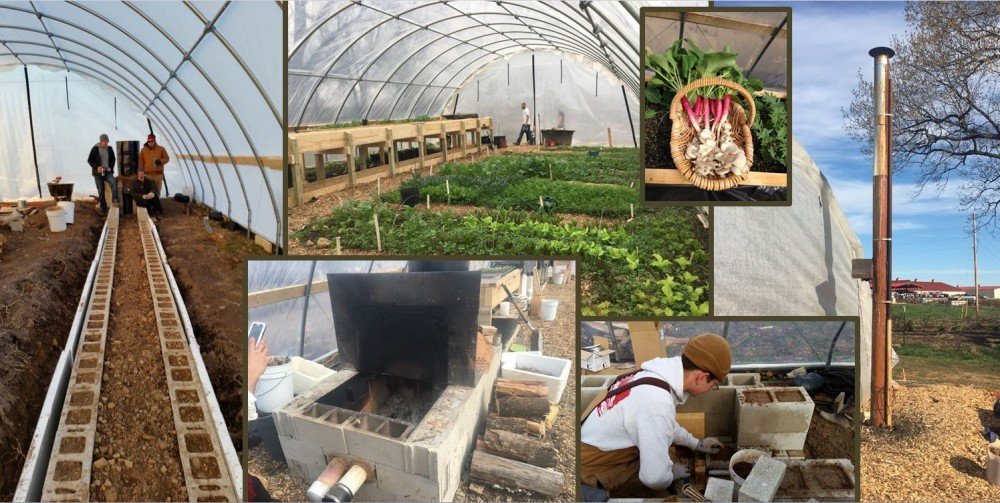

Folks at a similar course in 2015 standing behind a large hugelkulture "nurselog" bed they constructed, seeded, and planted.

What's this course all about?

The overarching theme of the course is an exploration of the practical details of building a land-based economy.

That is, how to work with the nature and character of land to build a productive ecosystem capable of providing the raw materials (food, fuel, medicine, craft materials, clothing materials, etc) for communities, even on marginal land like Windward's.

We will explore these concepts by working directly with the primary economy of plant-based ecosystems - making water retentive growing spaces, conditioning the soil in native ecosystems, and propagating and planting productive native shubs, trees, and herbs.

Over the 3 days we will explore...

Windward's village-Scale Permaculture Systems

On day one, we will tour of the Windward's main hillside and it's permaculture designed systems.

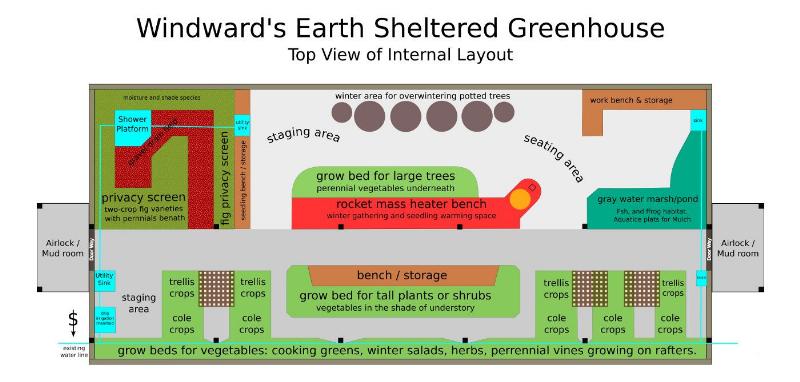

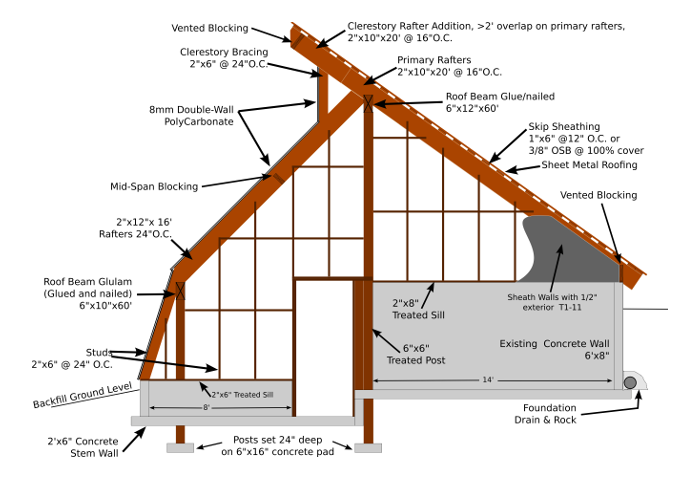

These includes intensive annual gardens, terraced grow beds planted with a polyculture of annual and perennial plants, contour hugelkultur gardens supporting a young woodland garden, pollinator garden, medicinal garden, greenhouses, community spaces, and more.

Water Harvesting Earthworks and Hugelkultur

A view of Windward's main hillside, with it's contour hugelkultur and young woodland garden.

In the afternoon on day one, we will build a hugelkultur "nurselog" garden bed on countour to prevent erosion and provide a body of soil to feed and nourish a developing food forest.

Building a Polyculture of Herbacious Plants for semi-arid food forests

Instructor, Andrew Schreiber, tours the medicinal section of a hugelkultur garden.

On day two we will finish the hugelkultur bed and then head to the outdoor clasroom to explore the process of designing a polyculture for our new bed.

We will explore plant morphology, life span, ecosystems services, synergistic interactions, and other considerations that affect the functional evolution of the bed in relation to our goals, as well as the whole-system of which it is a part.

We will then take the seeds of these plants and begin treating them in preparation for planting.

In addition to working with seeds, we will learn to propagate herbs by division, which we will get to practice on several species of plants.

Agroforestry, Silvopasture, and Tree Planting.

A view of a contour slash windrow being constructed in 2016

On day three we will use simple tools to layout contour lines in a silvopasture system, and then move slash (branches and logs) from stewardship forestry work onto the contour lines to create windrows to be planted as multifunctional hedgerows in the future.

We will explore the simple and subtle benefits of this kind of slash treatment, and how it helps condition the soil in preparation for planting trees. Next we will look at an older windrow and begin to plant a polyculture of trees and shrubs that will form a hedgerow / living fence.

the nursery with the trees we plan to plant

Throughout this process we will be discussing the broad acre stewardship forestry work at Windward, and explore the multi-faceted approach to ecosystem management aiming to generate a variety of materials (such as basketry whips, firewood, food, medicine, and animal forage) for the Windward community.

Other Details

Cost and Registration

The price of the course is $30 ($10 per day).

Living closely with the land in a cooperative and intergenerational community enables instructors Windward to offer in-depth educational experiences for next to nothing.

You can can continue the cycle of paying-it-forward by letting your friends know of the course and the other opportunities offered by the Windward such as three month apprenticeships and our annual open house event

Payment can be made via paypal (see button below), check or cash in the mail.

There are only 30 slots available! RSVP at

Windward@gorge.net to reserve your place.

Registration has been extended to March 15th.

Arrival, Departure and Accommodations

We like to keep departure times flexible in case you want a little more time the hang out, connect, spend time in the forest, and otherwise not rush back to the city.

Participants are encouraged to arrive a day early (on the 26th) and depart on the 30th.

The accommodations are primarily camping in our 40 acre campground.

The campground features a covered camping structure with 8 large bunks, as well as a multitude spaces for car camping.

If there is enough interest due to inclement weather or temperature sensitive individuals, we can also make available a cabin which is still partially under construction for the use of folks to set up their sleeping bags out of the elements.

)

)