Jacob,

Thanks.

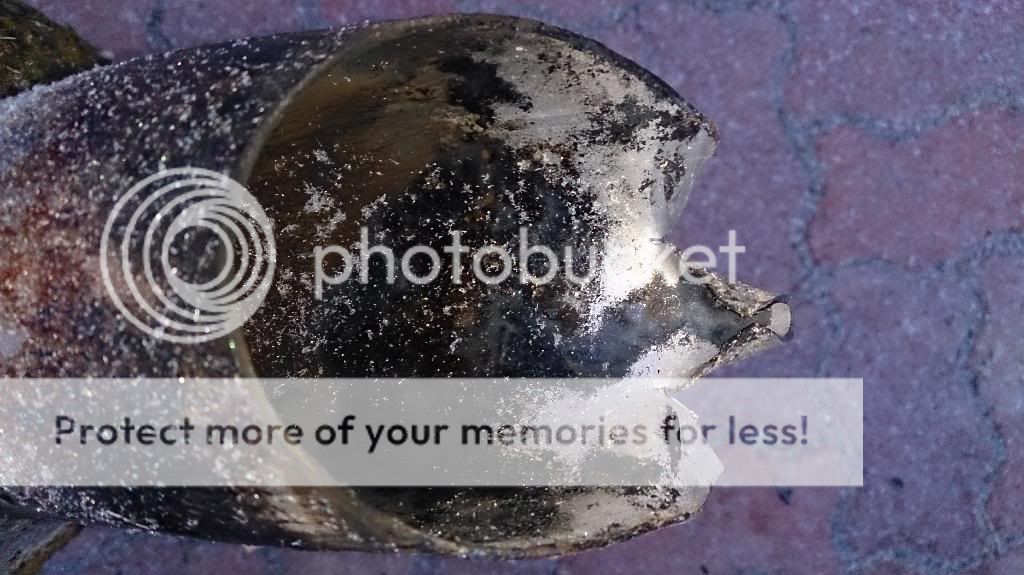

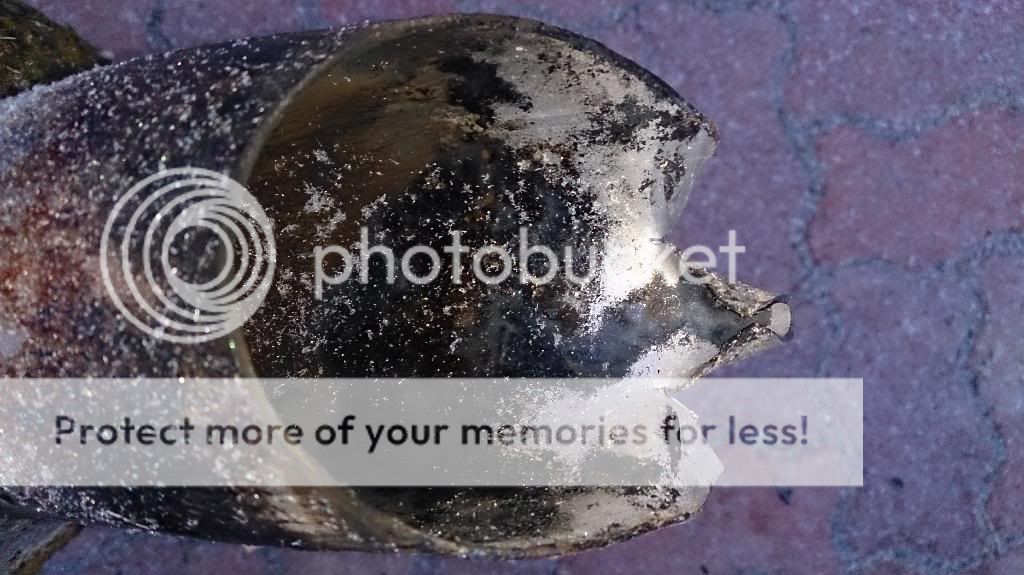

The feeder is just a couple of pieces of 3in exhaust pipe-- an 18in straight piece and a bent slant tip. I made a couple of cuts on the end of the tip and bent the center piece into a crude peg shape.

The bottom of the pellet feeder is an iron trivet with three 1in bolts as legs.

The peg rests in one of the holes in the trivet. The edge of the feed tube helps control the flow of pellets.

[/URL]

The stove's outstanding draw prevents the feeder from backdrafting.

The barrel is a 7 gallon steel heavy gauge with a ring clamp lid. I picked it up at a local salvage yard.

I'm about to experiment with insulating the feed tube on this one-- I've got some ceramic wool and S/S band clamps that should do the trick. With the pellet feeder, it's not an issue, but when I burn it with just wood, the tremendous heat ignites all of the fuel in the feed tube all at once and causes the system choke itself down with embers.

I haven't used a stove like this for an extended period of time, and this one is only a couple of months old, but I know that the stovepipe doesn't hold up very well at the bottom edge of the feed tube where temps are highest. The barrel, however, is far more durable. Using the pellet feeder exclusively would make a system such as this last much longer-- the feeder setup keeps the fire in the center of the barrel and maintains a consistent burn rate. Although it remains to be seen, I suspect that the feed tube will hold up a bit longer when insulated.

This little stove just has a chimney, not a heat riser, and insulating it would defeat the purpose since a lot of radiant heat is emitted from the chimney itself.

I would not consider ones of these stoves to be as efficient or hold more wood than a "conventional" RMH, but they do produce high enough temps to result in a very clean burn.

Check out this thread to see the small format RMH I built that includes a pellet feeder.

https://permies.com/t/22486/rocket-stoves/mini-rocket-mass-heater

[/URL]

[/URL]