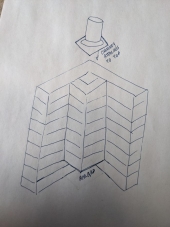

Pavers would just be a structural base, same with laid-up bricks. Cob makes beautiful organic forms, but a cob finish on a bench would be constantly shedding dust and getting pants dirty. You need a shield or sealer, like lime plaster or tiles or an oil that strengthens cob surfaces. Bricks can be made organic as a seat, stone slabs not so much.