I'd recommend you consider a batch box unless you like sitting and tending a stove for hours on end - the fuel burns fast so you need to "store the heat" with a good thermal mass or start with a 30-55 gallon barrel or propane tank (single, double or triple high stacks). Most "J" feeds will burn the wood down in less than 30-40 minutes so you are chained to tending a "J" feed rocket stove... build a "batch box" which is much more friendly... but be sure to plan how you will store the heat from burning wood (about 8,000 btu/pound for wood/pellets) How many btu(s) do you need per hour for heating a space? Depends on how much thermal storage and insulation "R" value to stop the heat loss... make an educated guess first using math then experiment to see how you can improve the situation.

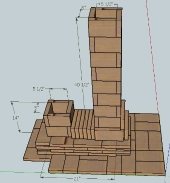

Here is the holy grail to a basic batch box rocket stove design.

The dimensions of the

batch box rocket stove are:

The assumption is, there should be a common base number to which all the other dimensions are related. Thank the forum senior members for all of the hard R&D work.

That BASE number is calculated from the diameter of the exhaust riser diameter.

BASE reference number is 72.34% of riser diameter. i.e. 4" diameter round or square exhaust riser x .7234 = 2.8936 BASE REFERENCE NUMBER

Width of firebox is 2 times BASE.

Height of firebox is 3 times BASE.

Depth of firebox is 4 to 5.5 times BASE.

Height of 'throat' port from firebox to riser is 2.2 times BASE.

Width of 'throat' port from firebox to riser is 0.5 times BASE.

Tuning the "throat" dimensions controls the gas mixing and burn turbulence which will greatly affect the stove draw... watch the flames and listen for the air rushing 'rocket sound'.

Height of exhaust riser is 8 to 10 times BASE, measured from the firebox floor. NEVER SMALLER ELSE IT WILL NOT DRAW WELL.

The firebox floor consists of a narrow flat surface the width of the firebox. Left and right there are 45 degree slopes in order to concentrate the glowing charcoals into the middle as the wood burns down. Those 45 degree chamfers are inclusive part of the dimensions of the firebox. In addition, there’s also a similar shaped piece at the rear bottom of the riser.

The total air inlet is 25% of riser cross section area (csa). Riser can be round, octagon or a square fire-brick shape... square works ok but not as optimum as round. For a first stove build it square using fire bricks - works ok.

P-channel is 5% riser csa.

Main inlet plus window wash is 20%. Main inlet could be larger when starting cold and is situated level with the floor of the firebox.

P-channel should be as wide as the port or slightly more, for the calculation of the 5% you should take the width of the port, not the actual width of the duct. This duct is hanging over the top of the port the same distance as the depth of the duct. Build the box first then add the p-channel port and optimize with a few test fires.

The back of the p-channel which is resting against the firebox rear wall has been cut away over the height of the overhang.

Exhaust is never smaller than the diameter of the riser.

Search here and on

http://donkey32.proboards.com/ for more build suggestions and details...