george auckland wrote:I live in Austin Tx. I want to put in a greenhouse then cool it with the cooling tubes under the grass beside it. I could fessibly dig 2 feet down. Is this doable, or a stupid idea?

John Carr wrote:

Anne Miller wrote:I have read a lot about rubble trench foundations here on the forum and the use of drain pipe and synthetic geotextile fabric is new to me.

https://permies.com/t/121202/rubble-trench-foundations

That's interesting, because elsewhere on the web it's always presented as necessary to have liner and a plastic drain at the bottom. E.g. https://www.buildnaturally.com/post/rubbletrench

If it were a shallow foundation and it would be relatively easy to remove the stuff years down the line, I might be willing. But I have to go 5' to get to frost depth and I don't want my grandchildren to have to excavate out a bunch of plastic. I like the idea of a compostable house.

2b. If your permit office requires a drain pipe

Note: Strictly speaking this is a modern addition to rubble trench detailing. But it is simple insurance to make sure that your structure lasts for centuries.

Crinstam Camp wrote:The manual says 13.5 is 100%

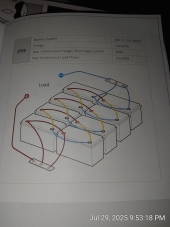

Crinstam Camp wrote:It should also mean we could add two more panels and switch it to a 3x2 setup?

David Baillie wrote:Chances are that your controller is pooched then.

it was 79ish it was about 267 watts, as it went above 80v the wattage started to drop.

Crinstam Camp wrote:I believe it is saying if it's over 60 volts, the controller will limit it.

Crinstam Camp wrote:

James Alun wrote:

Josh Hoffman wrote:

James Alun wrote:Yes but you haven't been keeping the current the same, you've been keeping the power the same.

Okay, I see what you are saying with me keeping the power constant and not the current in my posts like I should be.

If his panel were producing 20 volts and 177 watts, it would be 91% efficient. That would be more inline with the tag on the panel.

But the 2 together are only producing the 177 watts.

So now there are 2 broad possibilities, well actually 3.

Either the panels aren't generating the power properly eg dirty, misaligned, very old etc.

Or the power is being lost somewhere eg very long cables, cables too small.

Or possibly measurement error eg measuring at the wrong time of day, measurement averaged instead of instantaneous, etc.

No, actually none of those are a possibility,