14

14

regards, Peter

9

9

regards, Peter

12

12

regards, Peter

7

7

regards, Peter

10

10

regards, Peter

10

10

regards, Peter

11

11

regards, Peter

8

8

regards, Peter

10

10

regards, Peter

3

3

7

7

6

6

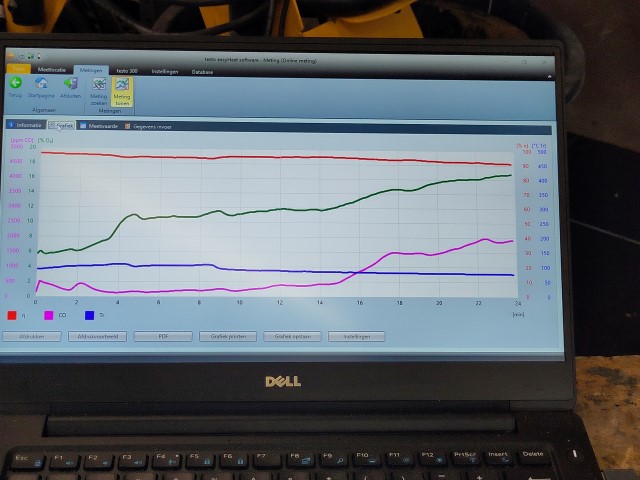

Alex Ronan wrote:Do you have any temperature readings inside the bell?

I am curious if the temperatures are high enough to allow for a modification to add a white oven.

regards, Peter

4

4

6

6

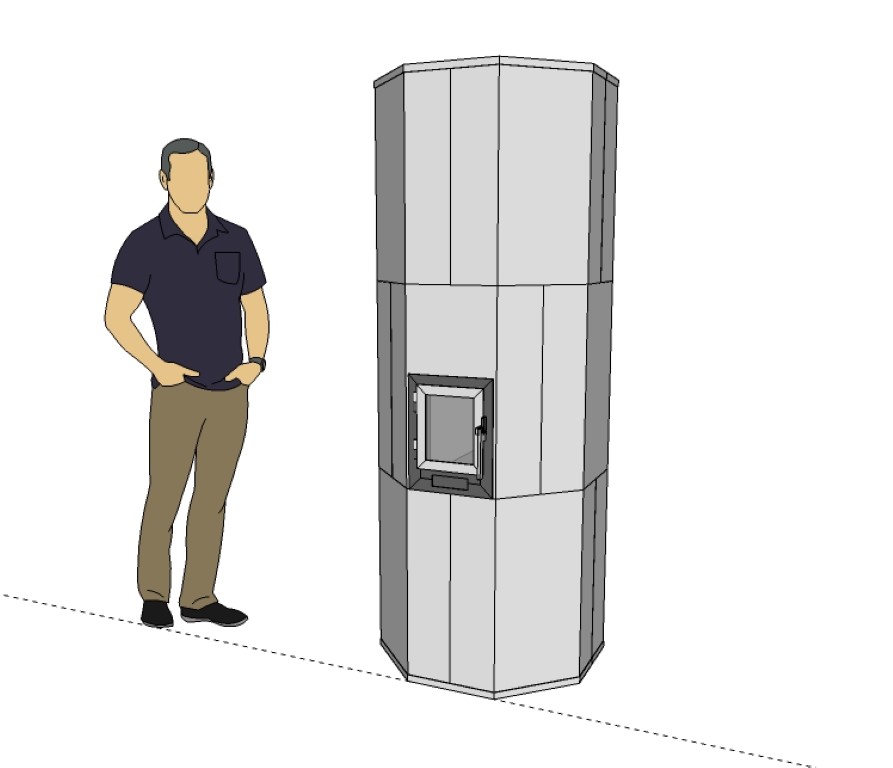

Scott Weinberg wrote:Peter-Having all the tools at hand, this intrigues me a great deal, ( Casting hi-frequency vibrator plate- Heavy bending break-lazer- large wet saw- CAD background and all the materials I presume this was considered a success?

Scott Weinberg wrote:Warning- there is more than one question! 1) Can we cast anywhere near the same cost as fire brick itself? Using larger bulk quantities of the castable material.

Scott Weinberg wrote:2) just an example, if I firebrick weights 2 Kg or 4.5 pounds, Will it take roughly the same weight of castable material to achieve the same volume of area? This I guess would answer question #1

Scott Weinberg wrote:3) In this upright "mass" was there a ISA formula that was followed for this sized shorty core?

Scott Weinberg wrote:4) The use of the steel exterior cladding I can see have many benefits on the building ease, does it serve as a quicker heat dissipater?

Scott Weinberg wrote:The stove looks great!

regards, Peter

7

7

regards, Peter

6

6

regards, Peter

4

4

Peter van den Berg wrote: totally agree, I think she's really cute, thank you

3

3

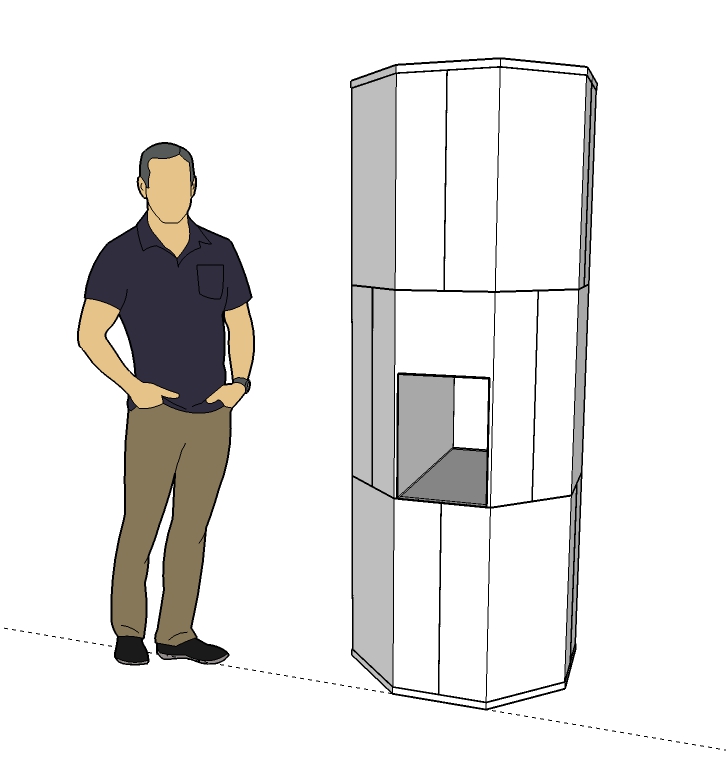

Peter van den Berg wrote:. The octagonal pepper shaker doesn't seem to be getting any drier now, so today the lid was put back on. .

6

6

Brandon Hands wrote:So are you going to start selling this flat pack sheet metal kit? Is it already for sale?

Brandon Hands wrote:Also, have you experimented with storing heat in water?

regards, Peter

5

5

Brandon Hands wrote:You may consider one of those blower fans that are commonly used to dry carpet after a flood. The impeller design allows them to work with high static pressure. Letting it force air though should dry it much faster and reduce possible corrosion

regards, Peter

5

5

Brandon Hands wrote:Very cool. I was thinking of designing a similar thing. I was considering the idea of using 85 gallon "salvage drums" which have an inner diameter of 26 inches (66cm). (Repainted with a high temp wood stove paint)

I hadn't gotten far enough to solve a method for connecting them together once stacked, but there might be a kind of band that could join them.

regards, Peter

2

2

Peter van den Berg wrote:

Or simply, fire the heater repeatedly. The inside of the steel panels aren't rust protected in this prototype. But for a business building this type it would be a good thing to have it all powder coated, also the inside.

2

2

Peter van den Berg wrote:

Brandon Hands wrote:So are you going to start selling this flat pack sheet metal kit? Is it already for sale?

It won't be me, going to sell this flat pack kit. And it isn't for sale at the moment by a third party. It is meant as an open source design, anybody who want to, can take the design and make a business out of it. I did this just to satisfy my own curiosity, could this be done in a reasonable way and with cheap mass? Up til now, it seems to be affirmative.

Brandon Hands wrote:Also, have you experimented with storing heat in water?

.

4

4

Brandon Hands wrote:

So are you going to start selling this flat pack sheet metal kit? Is it already for sale?

5

5

7

7

4

4

" All that is gold does not glitter; not all those who wander are lost; the old that is strong does not wither; deep roots are not reached by the frost. " J. R. R. TOLKIEN

8

8

sara ventura wrote:-I was under the impression that concrete should be avoided on areas of highest temperatures, but here the pavers are right into the path of the gases exiting the core. Will this affect its longevity?

So your question was already answered, please read carefully.Since the core spews the hottest gases forward instead of upward, only a limited number of firebricks are needed directly above the firebox to protect it.

sara ventura wrote:-Have you calculated the minimum area around the core to ensure optimal gas flow?

sara ventura wrote:Do you think this design would allow down scaling? It's great for a workshop, but in my experience around here, space in workshops is always scarce.

regards, Peter

6

6

There aren't pavers in the path of the hottest gases, but firebricks instead, five to be precise.

sara ventura wrote:

-Have you calculated the minimum area around the core to ensure optimal gas flow?

Yes, of course I did. Forgot the exact numbers since it's concept but it's sufficient, no doubt about.

" All that is gold does not glitter; not all those who wander are lost; the old that is strong does not wither; deep roots are not reached by the frost. " J. R. R. TOLKIEN

9

9

sara ventura wrote:I didn't put it right, of course it's calculated, I meant to say If there's an established formula to calculate this transit area around the core.

regards, Peter

4

4

4

4

6

6

T Cool wrote:Maybe for the wall mass of the bell, bricks need to be like in this draw of G. E. Asp

T Cool wrote:In my opinion the purpose of mass is to be like a thermal battery, make a fire for a maximum of 90 minutes, then 8-12 hours discharging in the house.

regards, Peter

| I agree. Here's the link: http://stoves2.com |