From 14 to 18 May the annual meeting of French mass stove builders was held in Montendre, organized by the

AFPMA. I was one of the participants and for this occasion I cobbled up a workshop together with Oliver Kreuser from

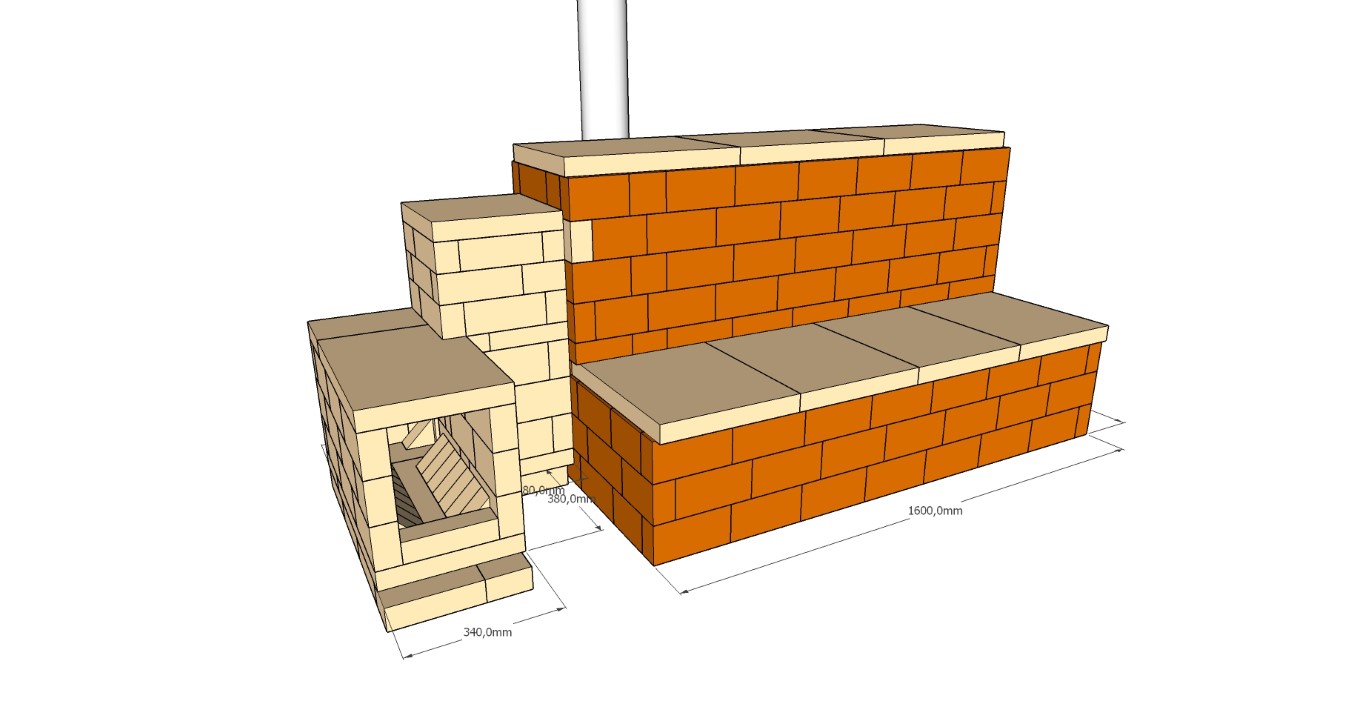

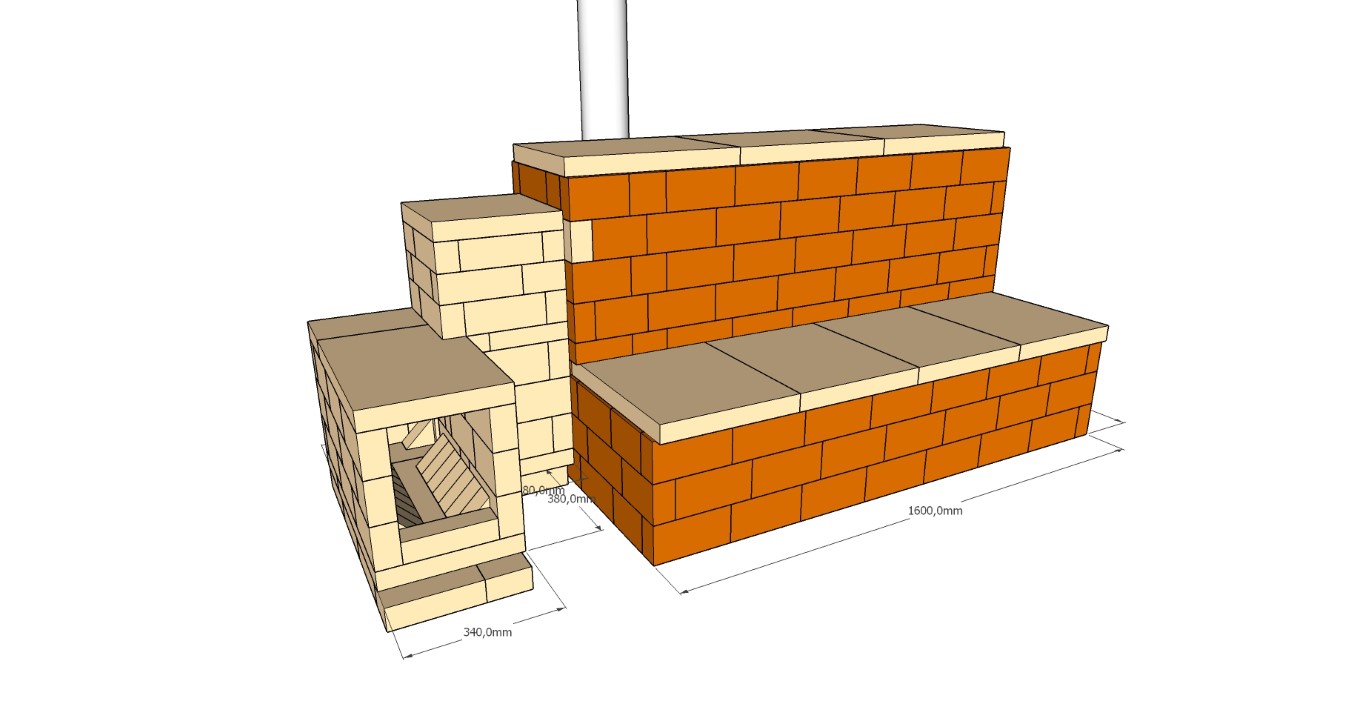

Terre des Feux. A large mass bench that had to be fed directly from the side by a Shorty sidewinder core. As a concept it was already an experiment but the exit of the core made it more complicated. Which was already facing to the side, was to be connected to the bench via a short tunnel. What the effect of this would be had not yet been tried, so I had no idea whether it would work.

A week or two before the meeting Adiel Shnior, a mass stove builder in Israel, emailed me asking for a phone conversation because he had some questions. During that conversation I also told him about my plans and his reaction was: why don't you make the exit of the core on the other side? Normally (with this core) the exit is in the same wall as the normal venturi port, he suggested to make it in the opposite wall. This was a nice idea, but of course not tested and I didn't know if it would work or not at all.

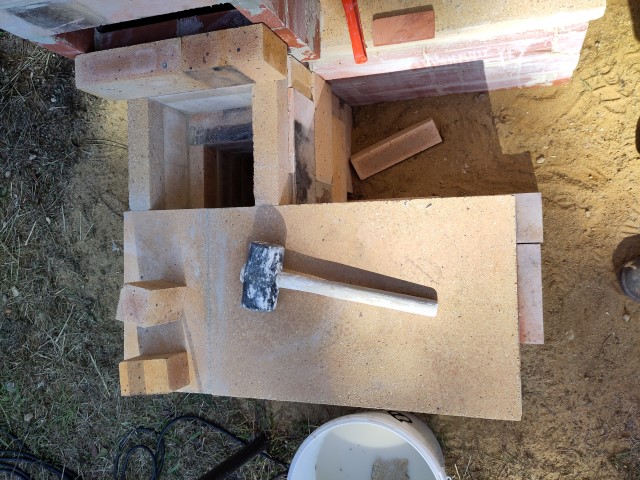

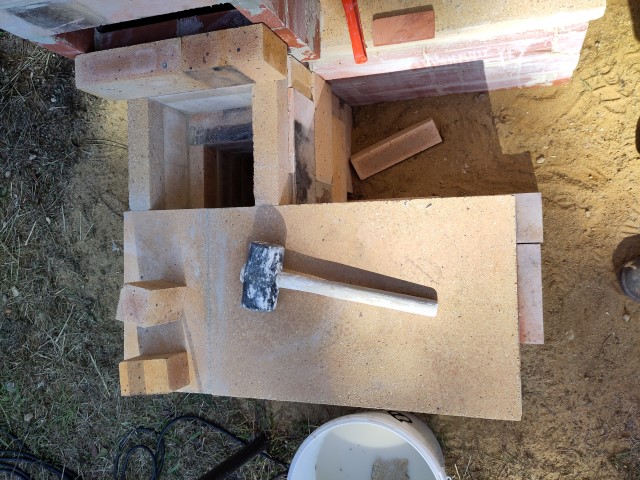

During construction the bench was built first and the core on the left side next to it, almost independently of the bench. When the core was next in line I decided then and there that Adiel's idea would be built, we still had some time to rebuild it if it really went completely wrong.

The bench is completely hollow, there are only three columns in it to support the seat. The exit is where the pipe comes up, the opening is right at the bottom and overly wide to give the gases room to round the bend. There is also a bypass provided, it is a T-piece that is incorporated in the pipe where the valve is housed. Out of sight, unfortunately.

Anyone who has followed the development of the Shorty knows that the lining in the riser is fitted on three sides. Left and right, and a double one around the port. Here it is different, the whole lining is turned 180 degrees, mainly in order to keep the double vortex a bit further away from the exit.

Above the gate the lining stops and the riser becomes wider, to give the gases the opportunity to expand.

Here it is a bit clearer how the core relates to the bench, in fact the core blows the gases into the backrest, which is therefore quite spaciously.

Here it is complete, the red bricks on top of the backrest are there to see if the extra mass would provide longer heat storage. In fact it didn't do much.

After the first attempts to keep the fire going we finally managed to dry the thing in about four hours. The next day someone brought a piece of ceramic glass for on top of the riser, so that everyone could see what was happening inside. The whole thing worked perfectly, completely smokeless even during refilling, nothing to smell, heat distribution over the bench very homogeneous in horizontal direction. The seat as a whole remained somewhat cooler, the backrest could have much more mass.

It was surprisingly pleasant to sit on the bench, the opportunity was therefore used extensively. The man on the bench is Oliver Kreuser, my co-builder in this project.

Later in the evening of May 17th, the glass on the riser really came into its own, here is a short video of what was visible.

https://pberg0.home.xs4all.nl/pictures/dev2025/benchrocket/MOVIE.mp4

All in all a very successful workshop, I came home very tired but very satisfied. For those who are interested in the actual construction, here is the

drawing in SketchUp 17 format.

12

12

10

10

7

7

10

10

4

4

6

6

6

6