Brett, Sounds good. I have the Better Farms 2nd Biogas plant. Is it the Same as the UN plant?

I am planning, if I do settle on a batch design, to use this plan but to use the square 260 gal containers instead of 50 gal drums. I'm having a hard time projecting my digester.

Currently I use about 17,138 buts worth of propane per day.

It seems like I need to load the batch with 92% water and 8% solids (by weight). So i'll put in 176 lbs of feedstock (sawdust, straw, hay, manure) and that should give me a total of about 320,000 btus (1,818 btus per lb). Does this all lok right so far??

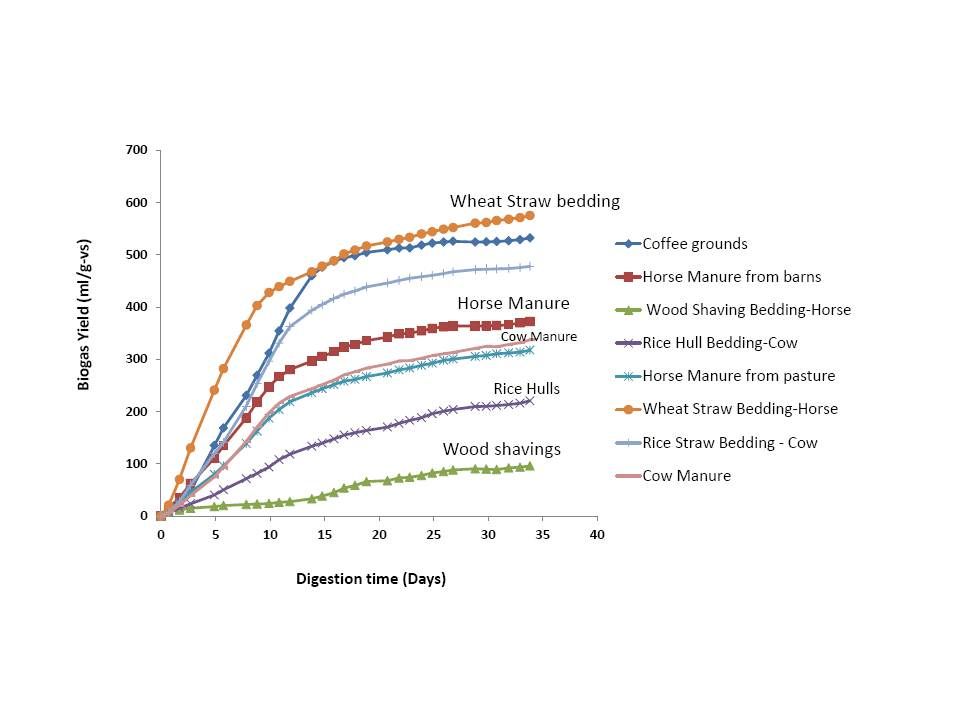

The problem I'm having is figuring out how much time will be needed. I'm looking at batch times differing from 30 days to 100 days!! At 30 days one cube (batch container) would give me about 10.667 btus per day. So with two cubes I could get over 20,000 btus worth of methane. BUT if my batch time needs to be 100 days then I would only be getting about 3,200 btus worth of methane per day. I could scale up to four cubes but even that would only give me 12,800 btus worth of methane per day. Sooooooo...What gives??

I really want to do methane. BUT the bad numbers look really bad and the good numbers look well, good! If it is a situation where I could get 80% of the methane in 40 days and then reload the batch and forget about the other 20%, that would be fine too. but, i'd like to know. Cause with my 80% model (if it is even realistic) I'd get about 256,000 btus in 40 days from one batch that gives me about 6,400 btus per day, so I could run 3-4 batches and that would give me my needed btu amount per day. I would start a new batch every 10 days. That is not that much work and would work well with my cleaning schedule.

Any thoughts?? I'd love to see photos once you've got them up.

I will use a parallel connected string of inter tubes as my collector and then run an underground pipe to my house. IF I can find the answers to my qs and IF those answers make me happy then I will do this and will also place photos.

How are you keeping the your batches warm? How many batches will be in your system?

I will be running a heat exchanger from a giant (70 cubic yard)

compost pile to each cube batch and using my wood fired hot water heater I'll be putting in water that is hot so the heat exchanger only ever has to keep the batches warm. The batches will be situated under the hallway of my barn, between the stalls, and will be very well insulated and then reburied. So, should be good.

Hope to hear from you, and others.