For that reason, I would question having a flat roof.

For that reason, I would question having a flat roof.

)

)

Regan Dixon wrote:I appreciate maximizing sunlight and using cheap, plentiful local building materials, and I understand that a corbelled or monolithic ceiling might be a bit much work.

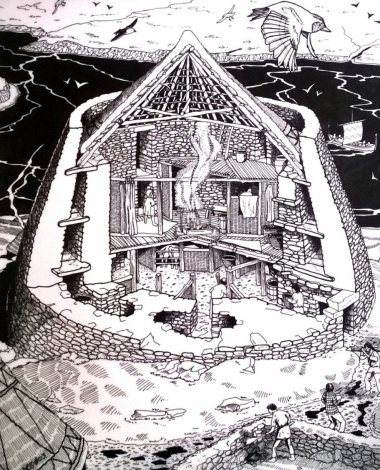

The traditional blackhouses seemed smaller than what you're designing, presumably limited in width by the timber available to support the roof. Though there is this picture/link I'm attaching that appears to be two houses parallel to each other, which may or may not be connected to one another. Are you married to the idea of a flat roof? I wonder if the idea of parallel traditional roofs over the different rooms would be practical, with interior gabions to support them, or whether that would pour water inside the house. (Hm, harvest fresh rainwater delivered right to point of use....) It rains in Scotland, doesn't it?For that reason, I would question having a flat roof.

(And, about a chimney--are you going traditional blackhouse, without one, or am I jumping the gun on details?)

http://www.photoeverywhere.co.uk/britain/westernisles/blackhouse3712.jpg

Crispin Pemberton-Pigott wrote:Gabion making by hand.

There is a set of hand operated equipment (two actually) for producing gabions from plain galv wire.

The idea is to make one of three types of mesh, then fasten it to a wire frame that is held on a large spindly jig. Then fold it up.

The three types of mesh are Diamond mesh (chain link) and Trinet which has triangular holes and Square Mesh which looks like diamond mesh turned 45 degrees. All three can be hand made under a tree.

The website is www.newdawnengineering.com under fence products.

The Trinet jig product was designed for Dam construction and bad be made with quite thick wire. The others are normally 11 gauge or thinner, 12 gauge being most common (2.5mm).

2

2

Crispin Pemberton-Pigott wrote:The idea of using 'fencing' as a deterrent or structural element is good in that you can make by hand precisely what you need. For example if you are making Square Mesh on site, you can make a single sheet of 'fence' as wide as you want - no joints for example over an entire roof.

You may have seen the Diamond Stucco Mesh on the same website. This was specifically designed to make a wire product that could hold cob or plaster without and backing - sort of like a chicken wire that is sized to hold plaster. It has a thickness of about 5mm meaning if you push it against a mould, the cement still gets behind half the wires and onto the other half.

The purpose is to be able to add a very strong reinforcement to plastered things like hay bales without investing a lot of money.

The Diamond Stucco Mesh machine is also used to make stainless steel mesh for bird cages. Unlike chicken wire (rigid hexagonal holes) it is stretchy so it can form over complex shapes like barrels. The machine is not easy to learn to use it - it takes a few days. Experts make about 25 m^2 per day (14mm holes). There are no machines in North America.

The Square Mesh has been made by hand down to 30x30mm. It is used to make gabions with internal dividers. The usual size is 76mm (3") holes.

The savings over buying fence may not be much where you live - check the cost of plain wire in bulk per kg and fence per kg first. The difference is the available savings. Most places it is 40% but watch out. Same warning for barbed wire.

If there is any interest in making water tanks from cement and mesh I can forward drawings for making a mould based on a galvanised corrugated iron water tank. We made dozens of such moulds for thousands of tanks in Southern Africa. The finished tank is 40mm thick (1-1/2"). Sizes were 1000 and 2000 Imperial gallons (4500/9000 litres)

|

Brace yourself while corporate america tries to sell us its things. Some day they will chill and use tiny ads.

The new gardening playing cards kickstarter is now live!

https://www.kickstarter.com/projects/paulwheaton/garden-cards

|